Warehouse epoxy flooring decisions directly impact your business operations, safety standards, and bottom line. The wrong choice leads to costly repairs, downtime, and potential safety hazards.

We at Wirth Floor have seen businesses struggle with flooring failures that could have been prevented with proper selection. This guide breaks down the essential factors for choosing the right warehouse epoxy system for your specific needs.

Understanding Warehouse Epoxy Flooring Requirements

Your warehouse floor must handle forklift loads that exceed 10,000 pounds without cracking or delamination. Standard concrete cannot withstand this punishment alone. Epoxy systems with compressive strength of at least 25 N/mm² provide the necessary foundation for heavy equipment operations. The Australian resinous flooring market shows epoxy as the fastest-growing segment precisely because it outperforms alternatives under extreme loads.

Heavy-Duty Load Capacity Standards

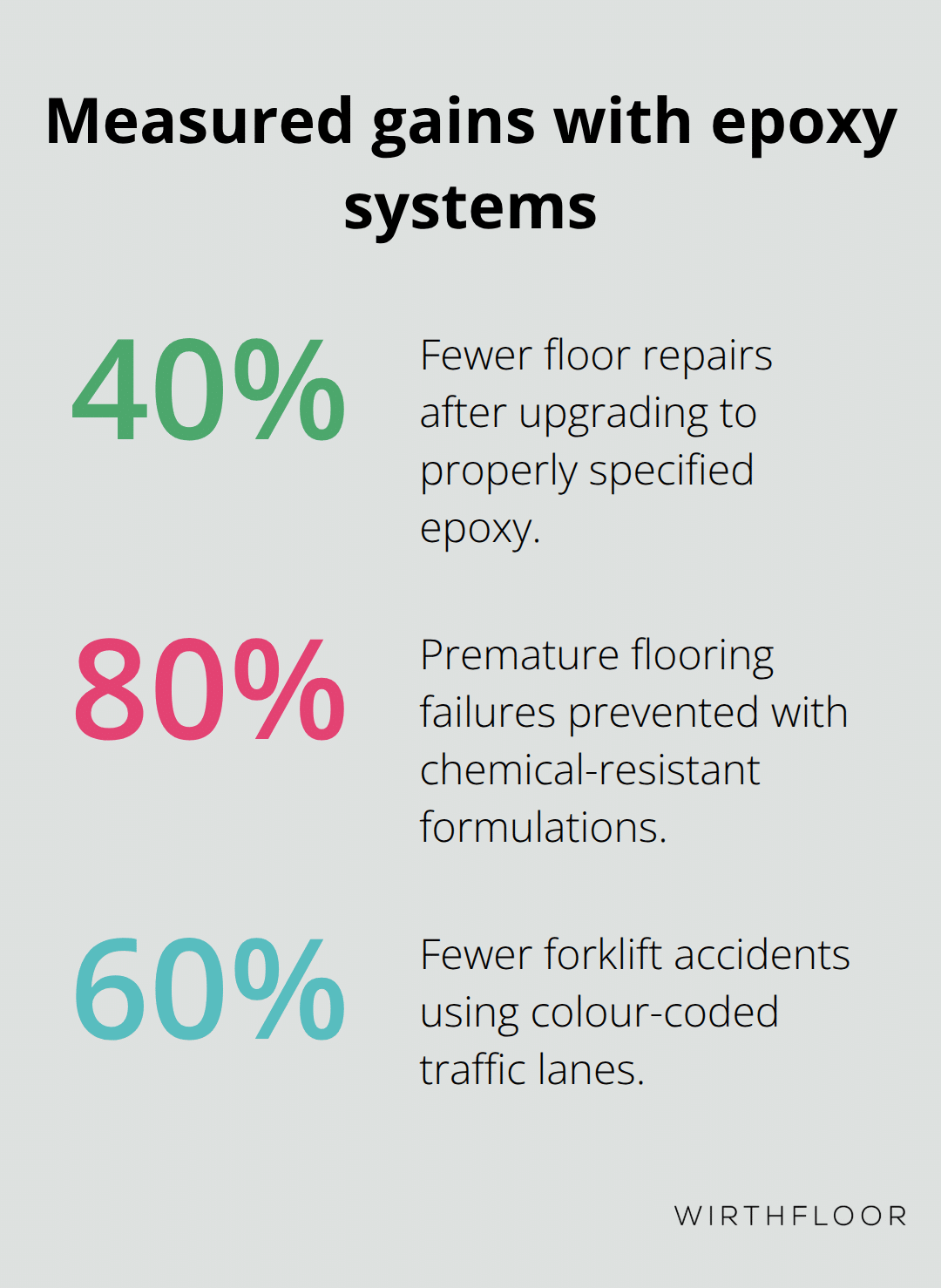

Warehouse operations demand floors that support concentrated point loads from pallet jacks, reach trucks, and order pickers. These machines create stress points that exceed 15,000 pounds per square inch at contact areas. High-performance, industrial-grade epoxy coatings distribute these loads across the substrate, preventing concrete failure and surface damage. Industrial facilities report 40% fewer floor repairs after upgrading from basic concrete to properly specified epoxy systems.

Chemical Resistance Requirements

Industrial operations expose floors to oils, solvents, acids, and alkaline cleaners daily. Generic epoxy fails within months when subjected to battery acid from forklifts or hydraulic fluid spills. Chemical-resistant epoxy formulations prevent pitting, erosion, and staining caused by aggressive substances like sulphuric acid, hydrochloric acid, and alkalis. Food processing facilities require floors that resist citric acid and sodium hypochlorite solutions (common in sanitisation protocols). The National Floor Safety Institute reports that proper chemical resistance prevents 80% of premature flooring failures in industrial settings.

Safety Performance Standards

Slip and fall incidents cost Australian businesses over $2 billion annually according to Safe Work Australia data. Anti-slip epoxy coatings with aluminium oxide aggregates provide enhanced safety, meeting workplace safety standards. Colour-coded systems using high-visibility yellows and reds for traffic lanes reduce forklift accidents by 60%. Photoluminescent additives in epoxy create emergency egress paths visible during power outages.

These performance requirements form the foundation for evaluating different epoxy systems and their suitability for your specific warehouse operations.

Key Factors When Selecting Epoxy Flooring Systems

Surface assessment determines epoxy system success more than any other factor. Concrete moisture content testing follows ASTM F2170 standards for determining relative humidity in concrete floor slabs. Calcium chloride tests reveal substrate conditions before application because research shows that up to 80% of epoxy floor failures stem from improper surface preparation. Oil-contaminated concrete requires shot blasting to 150 grit profile depth, while laitance removal needs diamond grinding to expose aggregate.

Surface Preparation Requirements

Temperature differentials between substrate and ambient air that exceed 5 degrees Celsius create adhesion problems that manifest as bubbles within the first year. Concrete surfaces must achieve proper mechanical profile through grinding or shot blasting. Dust and debris removal becomes critical before primer application (even microscopic particles compromise bond strength). Professional contractors test concrete pH levels because alkaline surfaces above 10 pH prevent proper epoxy adhesion.

Thickness Specifications for Warehouse Applications

Standard warehouse traffic requires minimum 6mm thick epoxy systems, while heavy forklift operations demand 10-15mm applications. Thin mil coatings under 2mm thickness fail under point loads from pallet jack wheels within months. Self-levelling epoxy systems at 3-6mm thickness handle moderate traffic but crack under concentrated loads that exceed 12,000 pounds. Mortar-filled epoxy at 10mm thickness withstands industrial abuse while providing chemical resistance superior to concrete alone.

Long-Term Cost Analysis

Maintenance frequency drops 85% when you select appropriate epoxy thickness for your application. Basic concrete requires resurfacing every 3-5 years at $15-25 per square metre, while properly specified epoxy lasts 20-30 years with minimal intervention. Labour costs for warehouse downtime during repairs exceed $5,000 per day for typical distribution centres (making prevention far more economical than reactive maintenance). Chemical-resistant epoxy prevents substrate damage that requires full floor replacement at $45-65 per square metre.

Smart warehouse operators calculate total ownership costs over 20 years rather than focus solely on initial installation prices. The Australian resinous flooring market projects 7.2% annual growth specifically because businesses recognise that proper specification prevents costly replacements. Different epoxy formulations offer varying performance characteristics that match specific operational requirements.

Which Epoxy System Matches Your Warehouse Needs

Self-Levelling Systems for High-Traffic Operations

Self-levelling epoxy systems at 3-6mm thickness handle moderate warehouse traffic while they provide smooth surfaces that facilitate equipment movement. These systems work best for distribution centres that process 500-1,000 pallets daily with electric pallet jacks and order pickers. The smooth finish reduces tyre wear on material handling equipment by 30% compared to rough concrete surfaces.

Concentrated loads from reach trucks that exceed 8,000 pounds create stress fractures within 18 months. Temperature fluctuations above 40 degrees Celsius cause expansion joints to fail, which leads to crack propagation through the coating system. Operators must consider these limitations when they evaluate self-levelling options for their facilities.

Mortar-Filled Systems for Heavy Industrial Applications

Mortar epoxy systems at 10-15mm thickness withstand punishment from 15-ton forklifts and automated guided vehicles in heavy manufacturing facilities. These systems incorporate silica sand or aluminium oxide aggregates that create compressive strength of 70-80 N/mm². Steel processing plants and automotive assembly facilities report zero floor failures after five years with properly installed mortar systems.

The thick profile allows for multiple recoats without height restrictions, which extends service life to 25-30 years. Installation requires 72-hour cure time compared to 24 hours for thinner systems, but prevents costly production shutdowns from floor repairs. Heavy-duty operations benefit most from this robust approach.

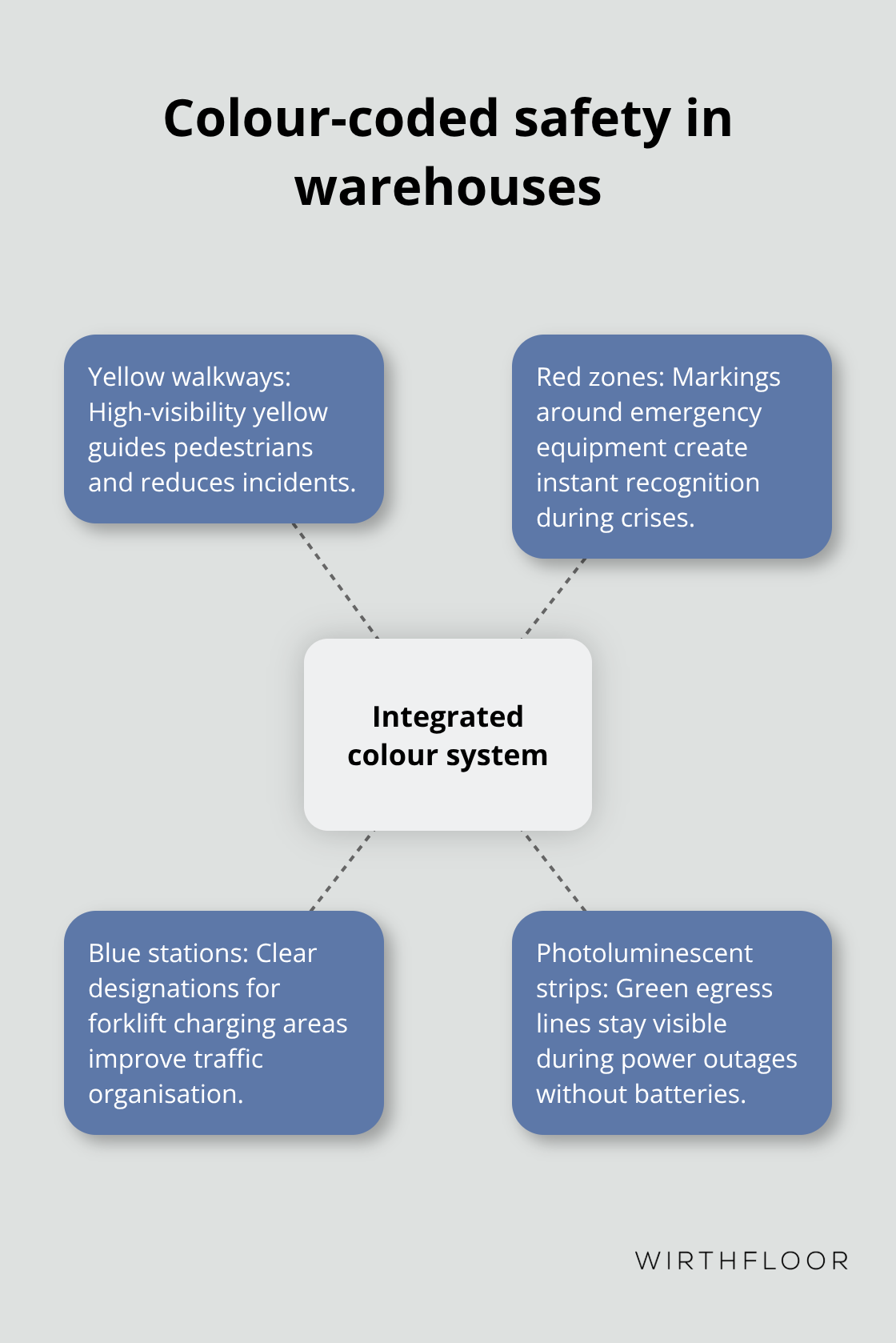

Colour-Coded Safety Integration

High-visibility yellow epoxy for pedestrian walkways reduces workplace accidents significantly. Red zones around emergency equipment create instant recognition during crisis situations, while blue markings designate forklift charging stations. Photoluminescent green strips provide emergency egress visibility during power outages (without battery backup requirements).

Colour integration during installation costs 15% more than standard grey systems but eliminates ongoing maintenance for painted safety lines. These painted lines wear away within six months under forklift traffic, making integrated colour systems more economical long-term. Safety markings become permanent parts of the floor structure rather than surface applications that require constant renewal.

Final Thoughts

Warehouse epoxy flooring selection demands careful evaluation of load requirements, chemical exposure, and safety needs. Your floor must withstand concentrated loads that exceed 15,000 pounds per square inch while it resists industrial chemicals and provides slip-resistant surfaces. Thickness specifications range from 6mm for standard operations to 15mm for heavy industrial applications.

Professional assessment prevents the 80% of failures that improper surface preparation and system selection cause. Concrete moisture tests, pH evaluation, and substrate profiles determine which epoxy formulation will perform reliably for 20-30 years. Temperature control during installation and proper cure times affect long-term durability significantly (making professional oversight essential for success).

The Australian resinous flooring market’s 7.2% annual growth reflects how businesses recognise that proper specification prevents costly replacements. Wirth Floor creates custom solutions that combine durability with aesthetics for commercial and industrial clients. Schedule a professional floor assessment to determine your specific requirements and receive detailed specifications for your warehouse application.