Concrete surface finishes standards determine the quality and durability of your flooring project. Poor surface preparation leads to costly repairs and premature failure.

We at Wirth Floor see property owners across Brisbane, Gold Coast, and Sunshine Coast struggle with substandard concrete work. Understanding these standards protects your investment and prevents common surface defects.

Types of Concrete Surface Finishes

Smooth Trowel Finishes for Precision Applications

Smooth trowel finishes create the flattest surface possible but demand perfect execution. We recommend this finish only when you plan polished concrete or need maximum smoothness for industrial equipment. The surface must have a non-slip finish to meet building code requirements, though many contractors fail this standard.

Hand trowels work for areas under 50 square metres, while power trowels handle larger commercial spaces efficiently. Temperature control during application prevents surface defects – concrete temperature between 10-32°C produces optimal results (weather conditions directly affect this timing). This finish becomes dangerously slippery when wet, which makes it unsuitable for outdoor applications or high-traffic areas without additional treatments.

Broom Finishes for Safety and Cost Control

Broom finishes provide superior slip resistance through fine ridges created when contractors drag a broom across semi-wet concrete. This technique costs 40% less than decorative alternatives while it delivers excellent traction for driveways and walkways. Apply the broom finish when concrete reaches thumbprint stage – typically 30-60 minutes after placement (weather conditions affect this timeline).

Deeper textures resist weather better but collect more dirt and require pressure wash annually. Too many contractors rush this process, which creates inconsistent patterns that compromise both appearance and safety performance.

Exposed Aggregate for Premium Applications

Exposed aggregate surfaces showcase decorative stones through controlled surface removal, which creates natural slip resistance and visual appeal. The water wash technique removes surface cement paste within 2-4 hours of placement and exposes aggregates to one-third their diameter. Australian Standard AS 3600 requires 20mm maximum aggregate size for structural applications, though 14mm produces better surface consistency.

This finish costs 60-80% more than standard broom work but lasts decades with minimal maintenance. Acid wash and seal every 3-5 years to maintain appearance and prevent stains. Poor timing during the wash process creates weak surfaces that dust and scale prematurely.

Each finish type requires specific quality standards and testing methods to meet Australian construction requirements.

Industry Standards for Concrete Finishes

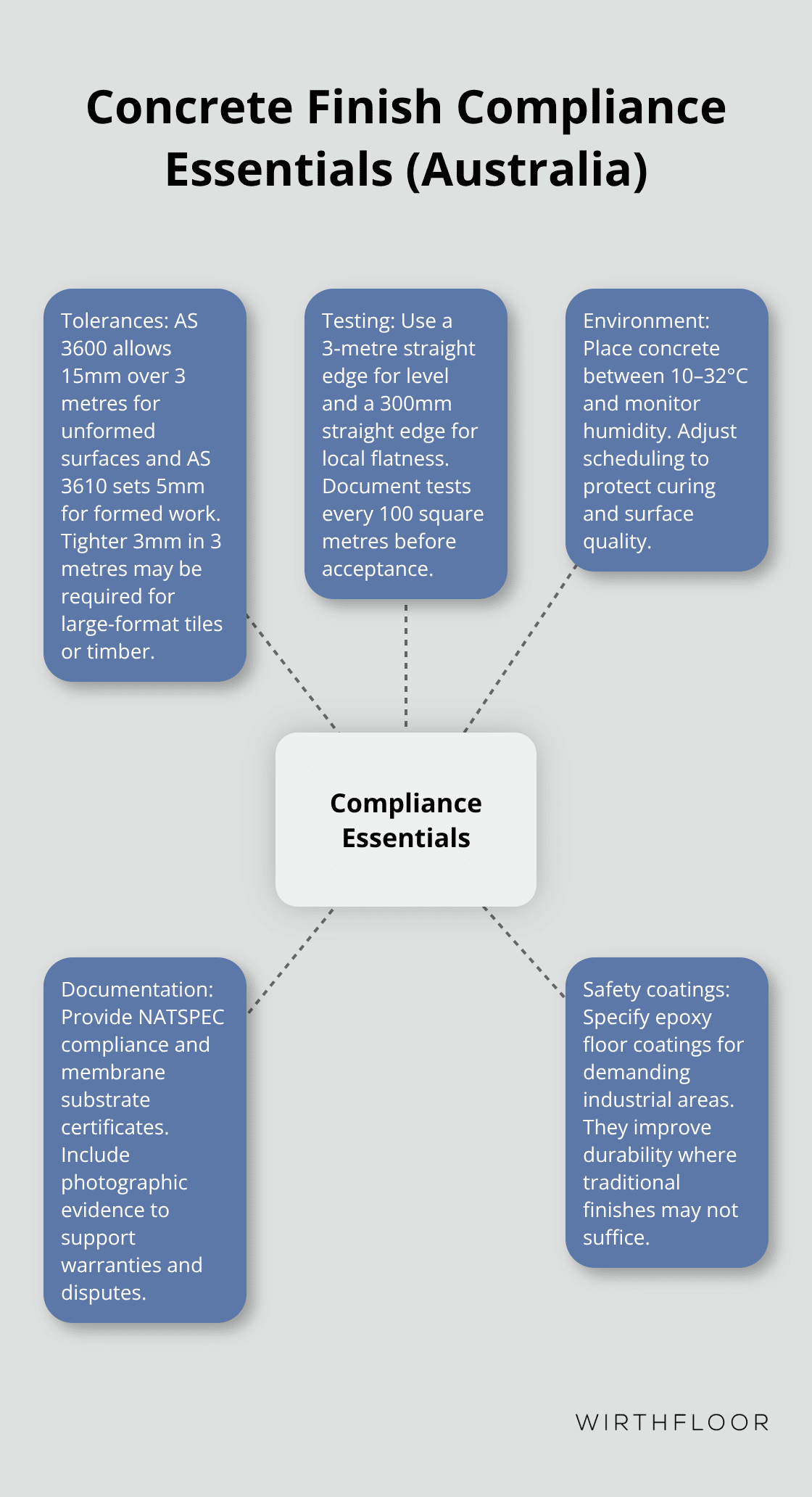

Australian Standard AS 3600 defines maximum tolerances of 15mm deviation over 3 metres for unformed concrete surfaces, while AS 3610 requires 5mm maximum deviation for formed surfaces. These standards separate professional work from amateur attempts that create expensive problems later. The 3mm in 3 metres tolerance that many contractors promise exceeds minimum requirements but becomes necessary when you install large-format tiles or timber floors that amplify surface irregularities.

AS 3600 Requirements for Structural Elements

AS 3600 establishes quality standards for unformed concrete elements that contractors must meet before project completion. The standard specifies surface level tolerances that prevent structural issues and finish failures. Concrete placed above 32°C or below 10°C fails these standards consistently because temperature affects curing rates and surface quality. Professional contractors monitor ambient conditions and adjust placement schedules to maintain compliance with these requirements.

Surface Level Testing Procedures

Surface level tests require a 3-metre straight edge placed randomly across the surface with measurements taken at the centre point. Flatness tests use a 300mm straight edge to measure local variations that affect finish quality. Professional contractors test every 100 square metres and document results before final acceptance. Temperature and humidity during placement directly affect these measurements and determine whether surfaces meet specified tolerances.

Quality Control Documentation Standards

NATSPEC specifications require written confirmation that surfaces meet tolerance requirements before applied finishes begin. Waterproof membrane applications demand substrate preparation certificates that verify surface quality meets manufacturer specifications. Contracts that exceed Building Code of Australia minimums provide legal protection when surfaces fail these enhanced standards. Photography documentation at test intervals creates evidence for warranty claims and quality disputes that arise months after completion.

Surface finish quality assessment involves visual inspection for blemishes, honeycombing, and colour variations that indicate poor workmanship. These defects often appear during the curing process and require immediate attention to prevent long-term performance issues. Epoxy floor coatings provide enhanced safety standards for industrial applications where traditional finishes may not meet durability requirements.

Common Surface Defects and Solutions

Surface cracks develop when concrete shrinks faster than expected, typically from rapid moisture loss or temperature changes during the first 24 hours. Plastic shrinkage cracks form while the concrete is still plastic and has not set. These hairline cracks widen over time and allow water penetration that damages the concrete structure. Map cracks indicate poor concrete mix design with excessive water content – water-cement ratios above 0.50 create weak surfaces that crack under normal loads. Settlement cracks occur when concrete placement continues over poorly compacted subgrade that shifts after loads apply.

Repair Methods That Actually Work

Crack injection with low-viscosity epoxy resins works for structural cracks wider than 0.3mm, while surface sealers handle hairline cracks effectively. Concrete replacement becomes necessary when cracks exceed 3mm width or show signs of movement. Temperature affects repair success rates – epoxy injection fails below 10°C because the material becomes too viscous to penetrate properly. Surface removal eliminates shallow cracks but reduces concrete strength when depth exceeds 5mm. Professional assessment determines whether cracks indicate structural problems that require evaluation before any repair work begins.

Prevention of Surface Deterioration

Surface deterioration occurs when surface cement paste lacks sufficient strength to resist abrasion, which happens when concrete dries too quickly in the first week. Concrete surfaces that deteriorate from day one indicate water-cement ratios exceeded 0.45 or workers finished while bleed water remained on the surface. Power trowels applied to wet concrete create a weak surface layer that deteriorates within months of completion. Proper cures require continuous moisture for seven days minimum – plastic covers or compounds prevent rapid moisture loss that causes surface weakness.

Colour Variation Solutions

Colour variations result from inconsistent water content, cement type changes, or uneven conditions across the surface. Temperature differences of 5°C between concrete batches create noticeable colour changes that become permanent after the cure completes. Calcium chloride accelerators darken concrete permanently and should never be used when colour consistency matters (this effect cannot be reversed).

Acid stains can minimise minor colour variations but cannot correct severe discolouration from construction errors. Full-depth coloured concrete costs 15% more than surface treatments but prevents colour loss from wear and weather exposure. Professional colour matches require sample panels cured under identical conditions to predict final appearance accurately.

Final Thoughts

Concrete surface finishes standards protect your investment and prevent costly repairs that plague poorly executed projects. AS 3600 tolerances of 15mm over 3 metres for unformed surfaces and AS 3610 requirements of 5mm for formed surfaces separate professional work from amateur attempts. Temperature control between 10-32°C during placement, proper cure for seven days minimum, and documented quality tests every 100 square metres create surfaces that last decades.

Long-term performance depends on how you match finish types to their intended use. Smooth trowel finishes work for polished applications but fail outdoors without slip-resistant treatments. Broom finishes provide cost-effective safety for walkways, while exposed aggregate delivers premium durability for high-traffic areas (water-cement ratios below 0.45 prevent surface deterioration).

Professional assessment before project completion identifies defects while correction remains economical. Independent test documentation and photographic evidence at critical stages protect your investment. Professional flooring contractors understand these standards and deliver surfaces that meet Australian requirements consistently.