Professional concrete polishing requires the right tools to achieve mirror-like finishes that last decades. The wrong equipment leads to uneven surfaces, excessive dust, and costly rework.

We at Wirth Floor have seen countless projects succeed or fail based on equipment choices. Quality concrete polishing equipment makes the difference between amateur results and professional-grade floors.

Which Machine Types Handle Different Project Sizes

Walk-Behind Grinders Excel in Smaller Spaces

Walk-behind floor grinders control the concrete polishing market for spaces under 5,000 square feet. These machines span from 20 to 36 inches in width, with the HTC 800 series setting performance standards for both cutting and polishing work. Single-head units perform best in residential garages and small commercial spaces, while triple-head planetary systems handle medium retail stores and office buildings with superior efficiency.

Weight distribution plays a vital role in results. Machines that weigh 800 to 1,200 pounds deliver optimal pressure for effective diamond tool contact without structural floor damage. Operators can manoeuvre these units through doorways and around tight corners (a major advantage in retrofit projects).

Ride-On Planetary Systems Dominate Large Projects

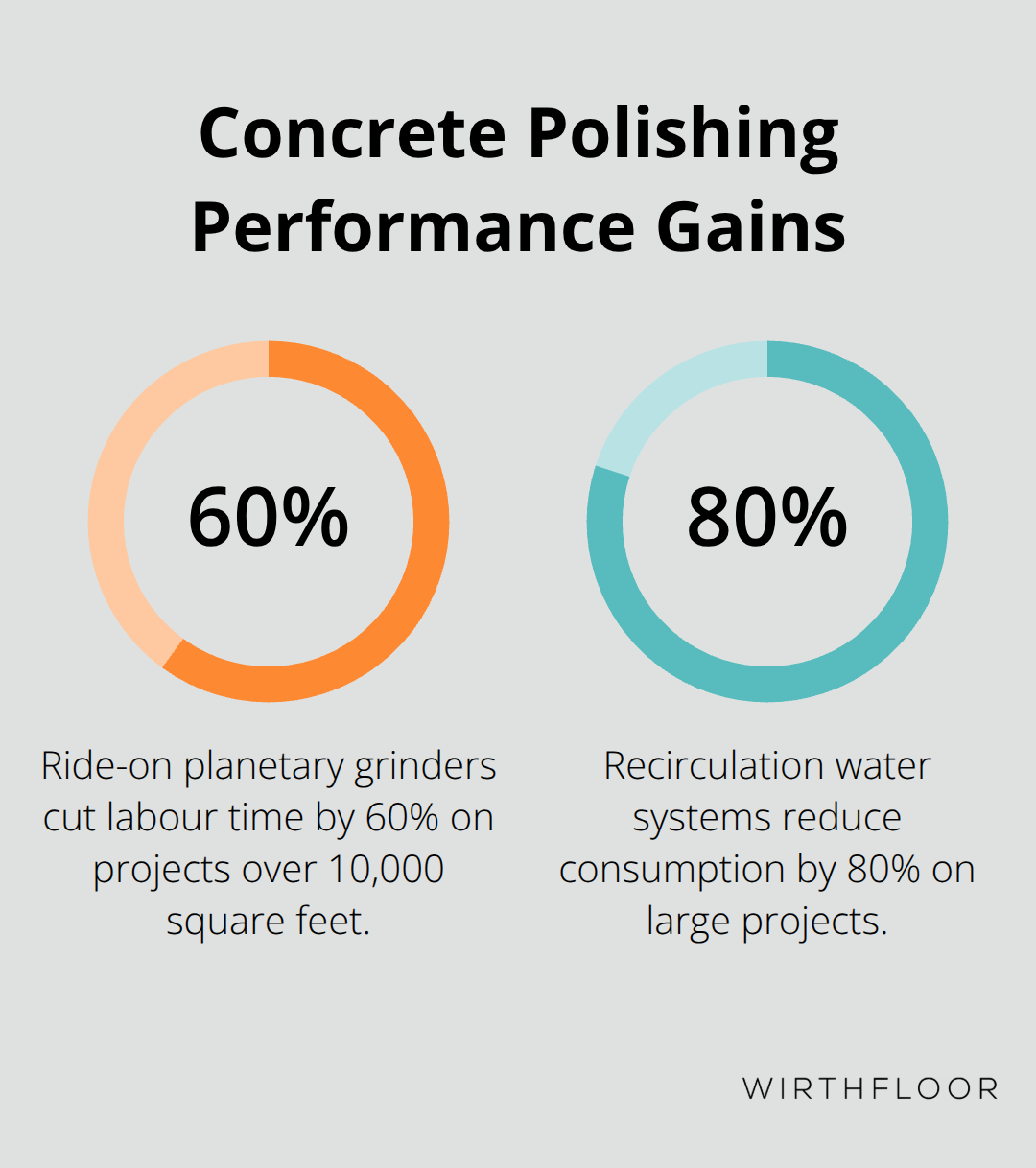

Ride-on planetary grinders become profitable on projects that exceed 10,000 square feet, cutting labour time by 60% compared to walk-behind options. Active planetary systems maintain uniform scratch patterns across warehouse floors and shopping centres, while passive planetary models often produce visible lines that need extra refinement passes.

Planetary grinders face competition from power trowels on large-scale projects due to production rate advantages. The investment pays off quickly on large commercial installations.

Edge Grinders Complete the Detail Work

Edge grinders fill gaps where larger machines cannot operate, particularly around columns, walls, and equipment foundations. Hand-held units from 4 to 7 inches handle detail work within 6 inches of obstacles, though they require skilled operators to match main floor finish quality.

Dust collection becomes more complex with edge equipment (proper ventilation systems are mandatory for health compliance). Smaller areas under 100 square metres cost significantly more per square metre due to equipment setup time and detailed edge work requirements. The right diamond tooling selection becomes even more important for these precision applications.

Which Diamond Tools Create Professional Results

Metal Bond Diamonds Power Through Initial Stages

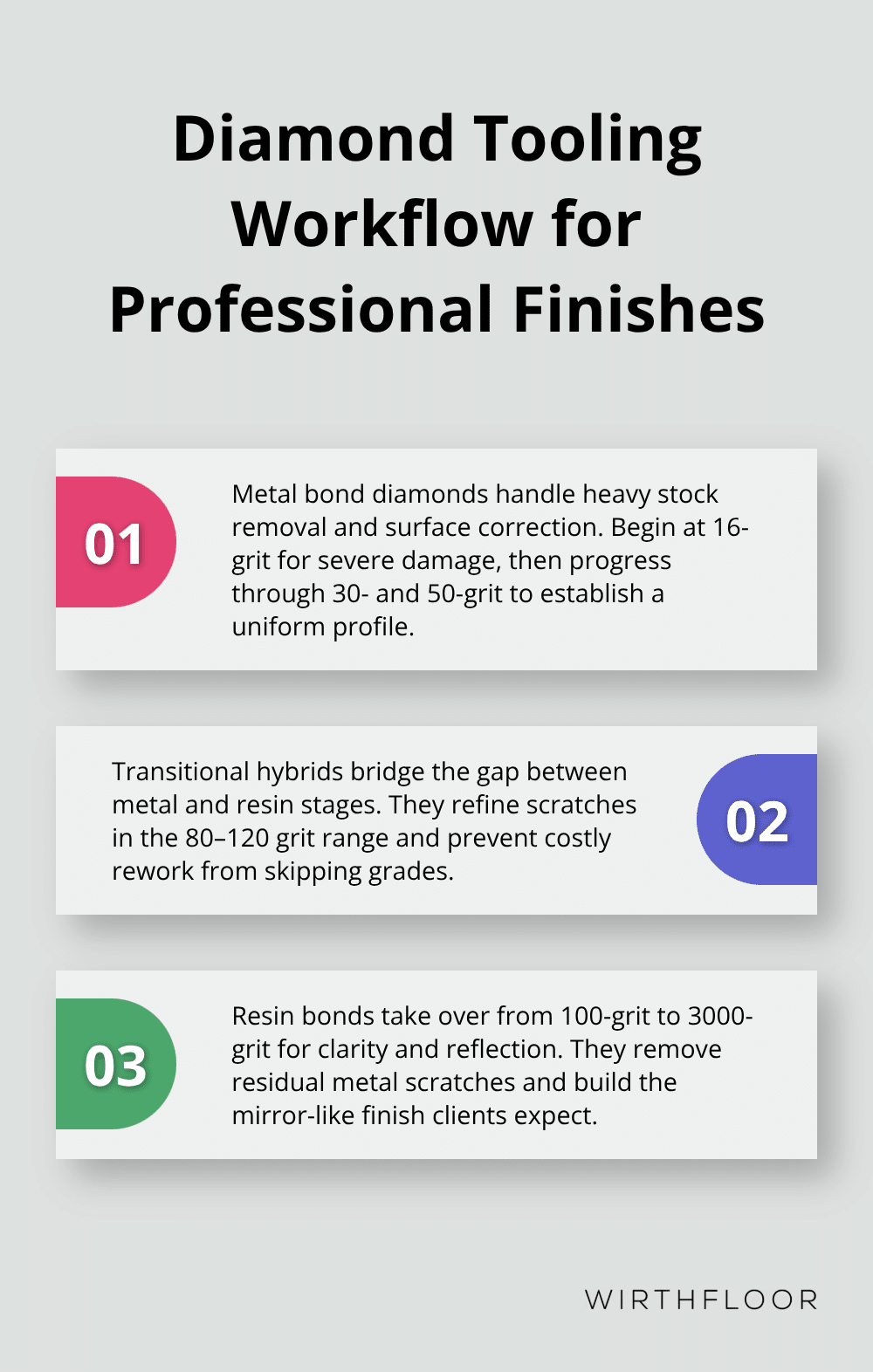

Metal bond diamonds tackle the heavy work during initial surface preparation, cutting through imperfections and old coatings with aggressive action. These tools contain diamond crystals locked in a metal matrix that wears away slowly, which exposes fresh cutting edges throughout the process. Start with 16-grit metal bonds for severe surface damage, then move through 30-grit and 50-grit sequences for proper preparation.

Metal bonds perform best on hard concrete above 3,500 PSI, where their aggressive nature prevents premature wear. Contractors who skip proper metal bond preparation face uneven polish results and shortened tool life in later stages. The metal matrix holds diamonds longer than softer alternatives, making these tools cost-effective for heavy-duty applications.

Resin Bonds Create the Final Mirror Finish

Resin bond diamonds take control from 100-grit onwards, using a softer matrix that releases diamonds faster for refined surface finishes. The 100-grit to 400-grit range removes metal bond scratches completely, while 800-grit to 3000-grit steps produce the mirror-like reflection that clients demand.

Quality resin bonds deliver superior performance compared to generic options but last twice as long on medium-hardness concrete. The investment pays off through consistent performance and reduced tool changes during long polishing sequences.

Transitional Tools Bridge the Gap

Hybrid transitional tools combine aggressive cutting with refined scratch patterns, preventing the common mistake of jumping directly from coarse metal bonds to fine resin bonds. This jump creates visible scratch lines that require expensive rework and additional passes.

Transitional diamonds work between 80-grit and 120-grit ranges, filling the critical gap where metal bonds end and resin bonds begin. These specialised tools save time and materials while maintaining consistent surface quality. Proper dust collection becomes even more important during these transitional stages to maintain visibility and tool performance.

What Support Equipment Prevents Project Failures

Industrial Dust Collection Systems Save Health and Money

Professional dust collection systems capture hazardous silica particles during concrete polishing, which prevents costly OSHA violations and protects worker health. Crystalline silica is a common mineral found in materials like sand, stone, concrete, and mortar, making proper dust control essential for worker safety. Industrial floor vacuums with HEPA filtration handle the massive dust volumes that dry polishing produces, while standard shop vacuums fail within hours on commercial projects. The Pullman Ermator S36 and similar industrial units process 400 CFM airflow rates that match high-production equipment demands.

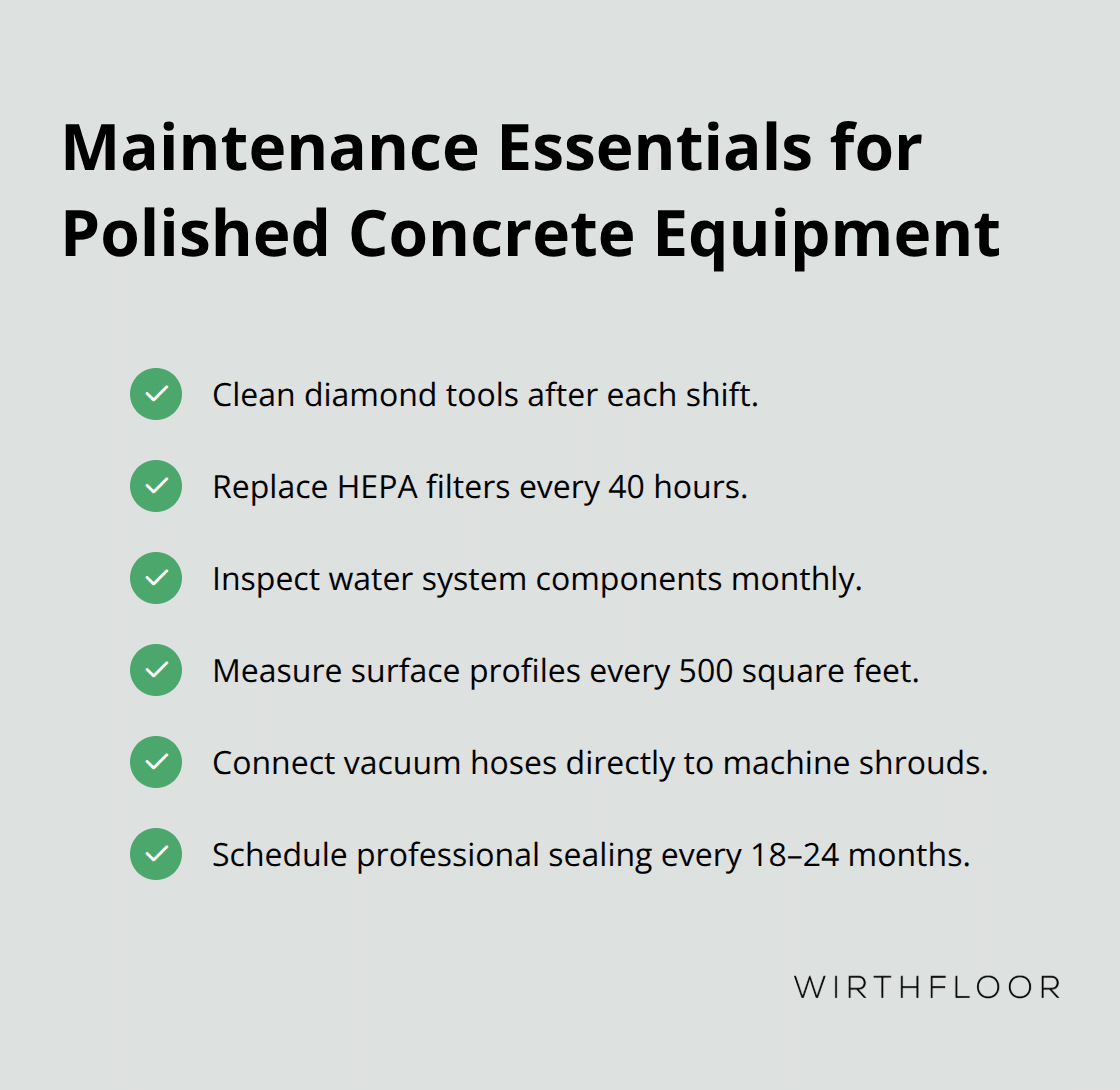

Contractors face fines up to $16,550 per violation for inadequate silica dust control under current OSHA regulations. Quality dust collection equipment pays for itself through avoided penalties and reduced cleanup time. Connect vacuum hoses directly to machine shrouds for maximum effectiveness, and replace HEPA filters every 40 hours of operation to maintain suction power.

Water Systems Control Heat and Extend Tool Life

Wet polishing systems reduce diamond tool temperatures compared to dry methods, which doubles tool life and improves surface quality. Water flow rates between 0.5 and 1.5 gallons per minute prevent diamond wear while they control airborne dust completely. Recirculation systems with settlement tanks reduce water consumption by 80% on large projects while they filter out concrete particles that damage pumps.

Surface Profile Gauges Eliminate Guesswork

Digital surface profile gauges measure concrete texture in microns, which removes guesswork from grit sequence decisions. The Surface Roughness Tester SRT-6210 provides readings that determine when to advance from metal bonds to transitional tools. Concrete surfaces require specific roughness ranges for proper densifier penetration and optimal polish results (measure surface profiles every 500 square feet to maintain consistent quality across large installations).

Professional sealing every 18-24 months prevents the $1,800 average replacement costs that neglected surfaces require. Proper maintenance extends surface life significantly while chemical resistance protects against industrial contaminants.

Final Thoughts

Concrete polishing equipment investments require careful project-specific planning. Walk-behind grinders suit residential and small commercial jobs under $15,000, while ride-on planetary systems justify their $80,000+ cost on warehouse projects that exceed 50,000 square feet. Mid-range contractors often start with quality walk-behind units and add specialised equipment as project demands grow.

Daily maintenance prevents costly breakdowns that can delay projects by weeks. Clean diamond tools after each shift, replace dust collection filters every 40 hours, and inspect water system components monthly. Professional-grade machines require $2,000-4,000 annual maintenance budgets but deliver consistent results across thousands of square feet.

DIY equipment rental rarely produces commercial-quality finishes. Consumer-grade polishers lack the weight and power needed for proper diamond tool contact, while inadequate dust collection creates health hazards and cleanup costs (professional contractors achieve mirror-like surfaces through equipment expertise and proper technique sequences that take years to master). Wirth Floor combines professional-grade concrete polishing equipment with specialised expertise to deliver exceptional results across Brisbane, Gold Coast, and Sunshine Coast projects.