Selecting the right industrial concrete flooring can make or break your facility’s operations. Poor flooring choices lead to costly repairs, safety hazards, and production delays.

We at Wirth Floor have seen countless facilities struggle with inadequate flooring systems. The key lies in matching your specific operational needs with the right concrete solution from day one.

What Load Requirements Define Your Industrial Floor Needs

Your facility’s load requirements determine everything about your concrete floor design. Heavy machinery, forklifts, and constant traffic patterns create specific demands that standard concrete cannot handle. Manufacturing plants typically experience loads between 5-15 kN per square metre, while distribution centres may see concentrated loads per square metre for rack systems and heavy equipment.

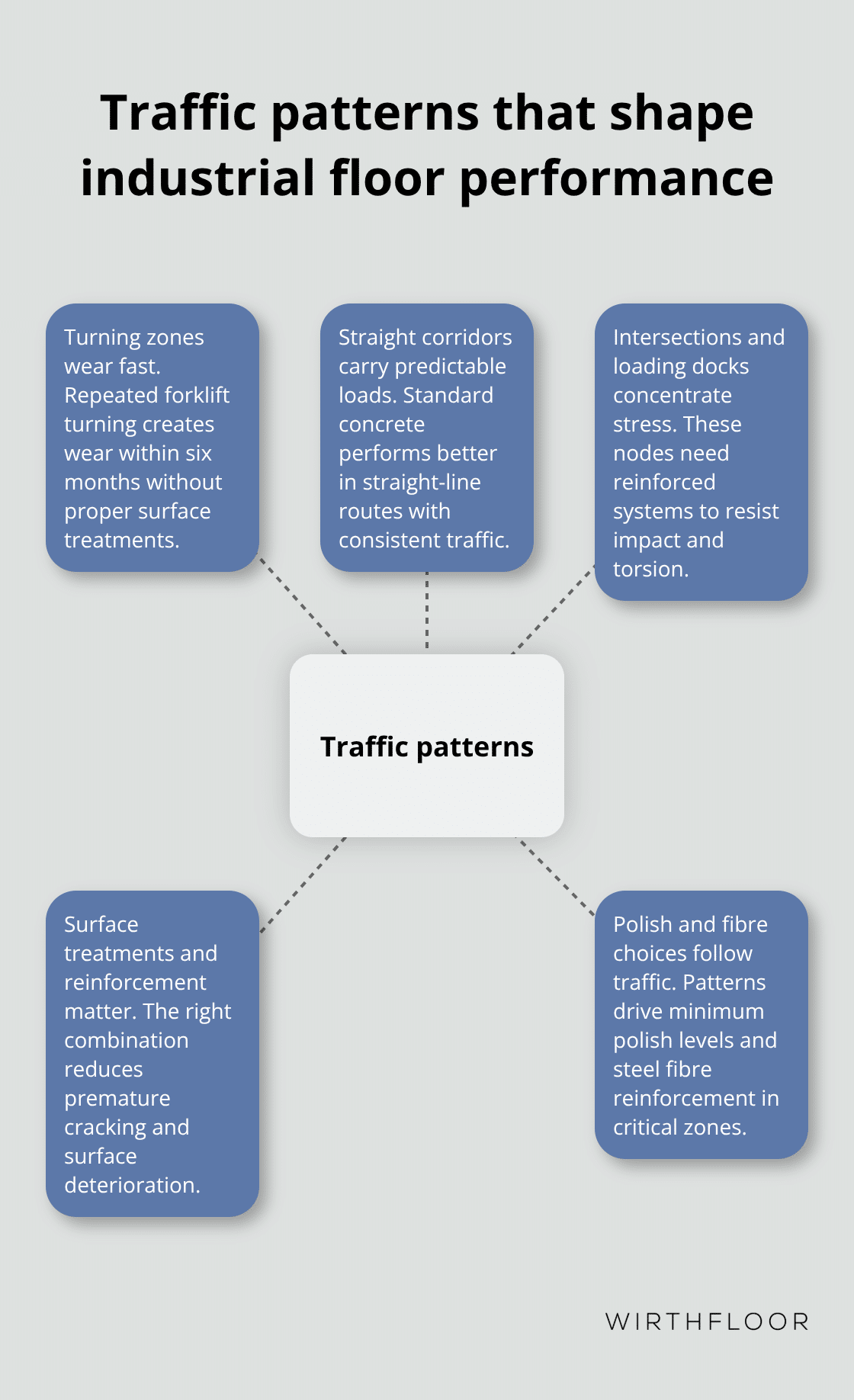

Traffic Patterns Shape Floor Performance

High-traffic zones need specialised attention beyond basic load calculations. Areas where forklifts turn repeatedly develop wear patterns within six months without proper surface treatments. Straight-line traffic corridors handle standard concrete better, but intersections and load docks require reinforced systems.

Traffic patterns determine your minimum polish requirements more than any other factor, with ACI 302.1R-04 specifications recommending steel fibre reinforcement in these critical zones to prevent premature cracks and surface deterioration.

Chemical Exposure Demands Protective Systems

Industrial environments expose floors to oils, acids, and cleaners daily. Food processors face constant moisture and sanitisers that destroy untreated concrete within two years. Chemical plants require floors resistant to specific compounds – what works for automotive oils fails against battery acids (pH levels vary dramatically between applications). Surface treatments like epoxy systems or specialised sealers become mandatory, not optional upgrades.

Maintenance Windows Control System Selection

Production schedules dictate which floor systems work for your facility. Twenty-four hour operations cannot accommodate multi-day installation processes that polished concrete requires. Epoxy systems cure faster but need proper ventilation during application. Facilities that run three shifts need floor solutions that install during minimal downtime periods (typically weekends or planned shutdowns).

Your operational constraints directly influence which concrete solutions will work best, which leads us to examine the specific types of industrial concrete systems available for different applications.

Which Industrial Concrete System Matches Your Operations

Polished concrete provides unmatched durability for facilities that need long-term performance without surface coatings. The mechanical process creates increasingly smooth surfaces through diamond abrasives, with aggregate exposure levels that determine final appearance and slip resistance. Brisbane Audi Centre demonstrates how polished concrete handles heavy foot traffic while it maintains aesthetic appeal. Manufacturing facilities benefit from improved ambient light that polished surfaces provide, which reduces energy costs significantly. The system works best where chemical exposure remains minimal and where the natural concrete appearance fits operational requirements.

Epoxy Systems Resist Chemical Damage

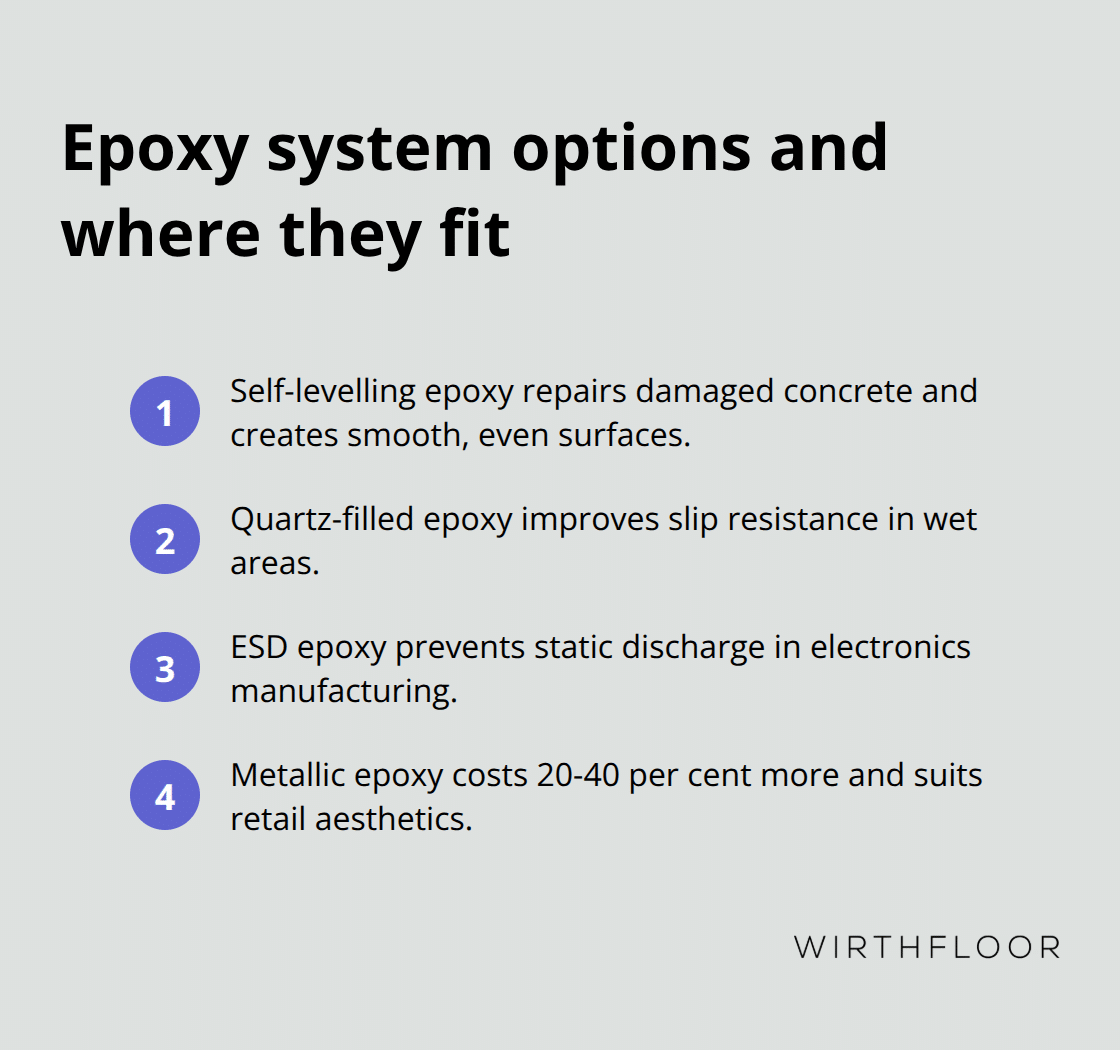

Epoxy coatings excel where chemical resistance becomes non-negotiable. Food processing plants require seamless surfaces that withstand constant cleaning with industrial sanitisers and acids. Two-part epoxy systems cure within 24-48 hours, which makes them practical for facilities with limited downtime windows.

Self-levelling epoxy repairs damaged concrete while it creates smooth surfaces for wheeled traffic. Quartz-filled epoxy provides slip resistance in wet environments, while ESD epoxy prevents static discharge in electronics manufacturing (metallic epoxy systems cost 20-40 per cent more than standard epoxy but deliver distinctive appearances for retail applications).

Specialty Treatments Target Specific Industries

Warehouse operations demand different solutions than pharmaceutical manufacturing. Distribution centres that handle frozen goods need joint systems like the Isedio ShieldJoint that accommodate temperature fluctuations without cracks. The Woolworths Distribution Centre installed 1170 linear metres of this system specifically for temperature-controlled environments. Heavy machinery areas require steel fibre reinforcement combined with hardener treatments to prevent surface damage from concentrated loads. Automotive facilities need oil-resistant surfaces, while chemical plants require acid-resistant systems rated for specific pH levels (these ratings must match your facility’s exact chemical exposure conditions).

Installation Speed Affects System Choice

Production schedules determine which systems work for your facility. Polished concrete requires multiple days of grinding and processing, which suits facilities with planned shutdowns or new construction timelines. Epoxy systems cure faster but need proper ventilation during application and cannot tolerate moisture during installation. Some facilities choose hybrid approaches where they install epoxy in high-chemical areas and polished concrete in general traffic zones.

The right system choice depends on how these performance characteristics align with your specific budget constraints and long-term operational costs. Your facility’s specific operational demands determine whether polished concrete, epoxy systems, or specialty coatings provide the best long-term value.

What Budget Factors Control Your Flooring Decision

Initial costs represent only a portion of total lifetime expenses according to ACI 302.1R specifications. Polished concrete systems cost between $3-8 per square foot but deliver decades of service with minimal maintenance. Epoxy systems range from $5-12 per square foot but need reapplication every 10-15 years (traffic conditions determine exact intervals). The real cost difference emerges through maintenance schedules where polished concrete requires only sweep and damp mop while epoxy systems need periodic recoat and potential repairs from chemical damage or heavy impacts.

Installation Schedules Impact Total Project Costs

Production downtime costs dwarf material expenses for most facilities. Manufacturing plants that shut down for floor installation lose significant revenue per day in lost production according to industry data. Polished concrete requires 3-7 days of process time which works for planned shutdowns or new construction but becomes prohibitive for facilities that operate continuously.

Epoxy systems cure within 24-48 hours but need proper temperature control and ventilation which can extend installation windows. Weekend installations cost 25-40 per cent more than weekday work but prevent production losses that exceed the premium charges.

Performance Specifications Drive Long-Term Value

Heavy machinery facilities need floors rated for point loads to prevent premature failure. Chemical process plants require pH resistance ratings that match specific exposure conditions where generic epoxy systems fail within months. Temperature fluctuations in cold storage facilities demand joint systems that handle thermal movement like the Isedio ShieldJoint used at Woolworths Distribution Centre. Performance specifications directly impact durability where underspecified floors fail within 2-3 years while properly designed systems operate for 20-30 years.

Cost Gaps Between Adequate and Premium Systems

The specification gap between adequate and inadequate systems often represents only 10-15 per cent cost difference but determines whether your floor becomes an asset or liability. Premium systems include steel fibre reinforcement, specialised aggregates, and surface treatments that standard concrete lacks. These upgrades prevent costly repairs and production disruptions that occur when floors fail under operational demands (replacement costs typically exceed initial installation by 300-500 per cent).

Final Thoughts

Industrial concrete flooring decisions require you to balance load requirements, chemical exposure, and operational constraints against budget realities. Your facility’s specific traffic patterns, maintenance windows, and performance demands determine whether polished concrete, epoxy systems, or specialty treatments provide optimal value. Professional assessment prevents costly mistakes that plague facilities with inadequate systems.

Load calculations, chemical resistance ratings, and installation timelines must align with your operational requirements. The 10-15 per cent cost difference between adequate and premium systems determines whether your floor becomes an asset or liability over its 20-30 year lifespan. Installation quality affects long-term performance more than material selection (poor installation creates problems where replacement costs exceed initial investment by 300-500 per cent).

Proper subgrade preparation, reinforcement placement, and surface treatments require experienced contractors who understand industrial demands. We at Wirth Floor help you avoid common specification mistakes while we deliver durable, low-maintenance floors that support your operations for decades. Contact us for custom flooring solutions that match your facility’s exact operational needs.