Polishing existing concrete slabs transforms worn surfaces into durable, attractive floors without the expense of replacement. This process works particularly well for warehouses, retail spaces, and residential areas across Brisbane and the Gold Coast.

We at Wirth Floor see property owners choosing concrete polishing for its cost-effectiveness and long-term durability. The right approach depends on your slab’s current condition and intended use.

How Do You Assess Your Concrete Slab Before Polishing

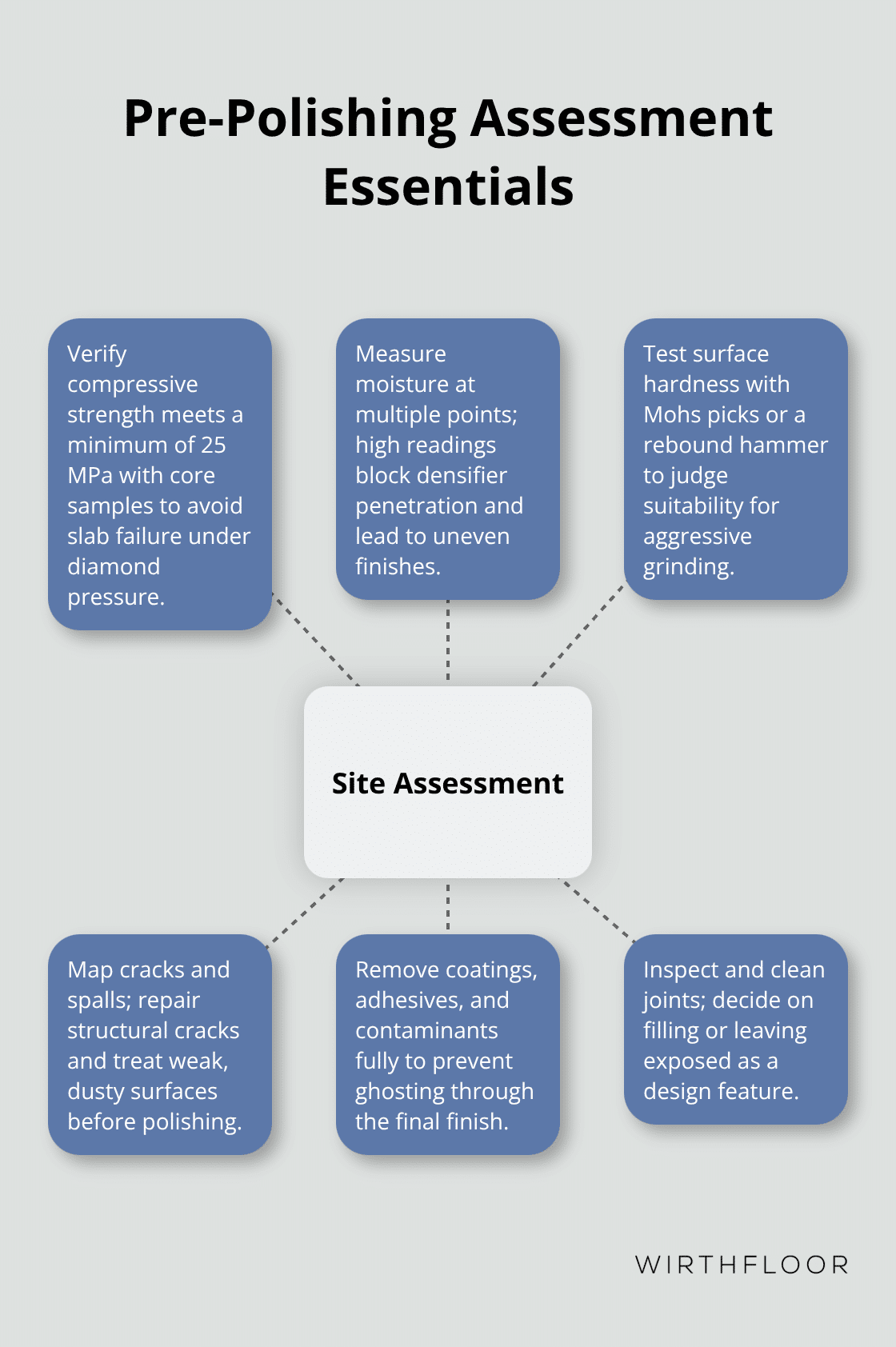

The success of concrete polishing depends entirely on proper assessment before any equipment touches your slab. Most failed polishing projects stem from skipped evaluation phases or rushed surface inspections. A concrete slab requires minimum 25 MPa compressive strength for successful polishing, and slabs below this threshold will simply crumble under diamond pressure.

Testing Concrete Strength and Moisture Content

Professional assessment starts with core samples to determine compressive strength and moisture levels. Moisture content above certain levels prevents proper densifier penetration and creates uneven finishes. Test moisture with a concrete meter at multiple points across your slab, particularly near walls and drainage areas where moisture typically accumulates.

Surface hardness tests with a Mohs pick or rebound hammer reveal whether your concrete can withstand aggressive treatment. Slabs with surface dust or flakes indicate weak concrete that needs chemical treatment before polishing begins.

Identifying and Addressing Surface Defects

Map every crack, spall, and surface defect before you start work. Hairline cracks under 3mm wide can remain and add character to the finished floor, but structural cracks require professional repair with polymer injection or routing and sealing methods.

Oil stains penetrate deep into concrete and need degreasing treatment with alkaline cleaners before any work begins. Remove all existing coatings, adhesives, and surface treatments completely (partial removal creates uneven patterns that show through the final polish).

Cleaning and Repair Requirements

Pressure wash the entire slab and allow 48-hour drying time before assessment. Fill spalls and holes larger than 10mm with colour-matched concrete repair compound, then allow full cure time per manufacturer specifications.

Joint sealant removal requires mechanical cutting rather than chemical methods to prevent contamination. Clean expansion joints thoroughly and decide whether to fill them with compound or leave them exposed as design features. Once you complete these preparation steps, you can select the appropriate equipment and begin the actual polishing process.

How Do You Polish Concrete With Professional Equipment

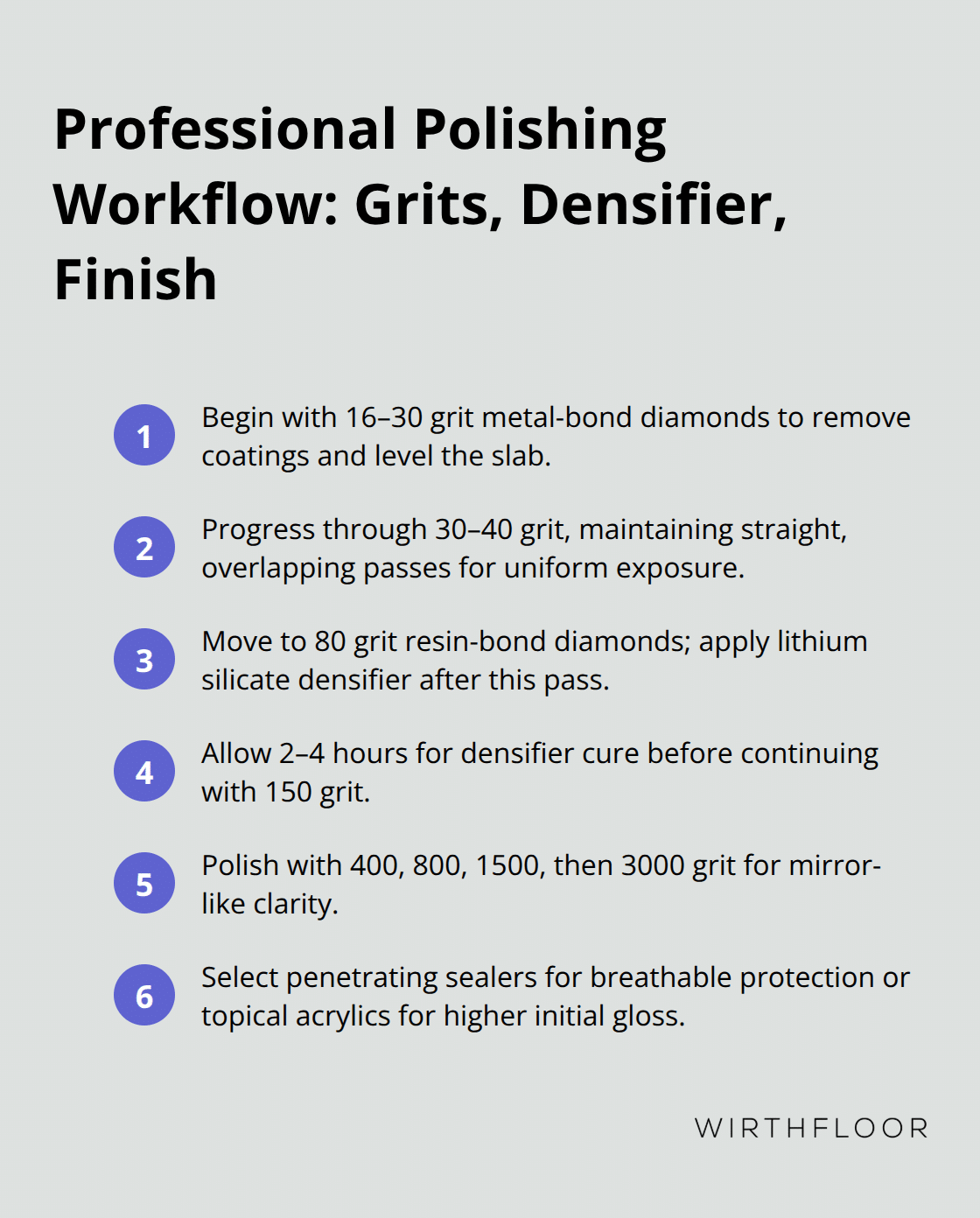

The diamond process starts with 16-30 grit metal-bonded diamonds to remove surface coatings and level the slab. This aggressive first pass creates the foundation for all subsequent work and typically removes 1-2mm of surface material. Progress through 30-40 grit, then 80 grit resin-bonded diamonds, with each pass that requires complete coverage in overlapping patterns. Skip grit levels and you get deep scratches that show through the final finish.

Initial Surface Preparation Steps

Start with coarse metal-bonded diamonds to address surface irregularities and existing coatings. The 16-30 grit stage removes paint, adhesive residue, and surface contaminants while exposing the concrete matrix. Move the equipment in straight, overlapping passes to maintain consistent surface preparation across the entire slab.

Check your progress frequently during this stage (uneven removal creates problems in later steps). The concrete surface should appear uniformly exposed with no remaining coating patches before you advance to finer grits.

Densifier Treatment for Maximum Hardness

Apply lithium silicate densifier after the 80 grit pass when concrete pores open optimally for penetration. The densifier chemically reacts with calcium hydroxide to create calcium silicate hydrate, which increases surface hardness. Allow 2-4 hours cure time before you continue with 150 grit diamonds.

Inadequate densifier penetration creates soft spots that polish unevenly and wear prematurely under traffic. Apply the densifier with a microfibre mop in thin, even coats to prevent pooling or streaking.

Final Polish and Sealer Selection

Complete the sequence with 400, 800, 1500, and 3000 grit diamonds for mirror-finish results. Each grit level removes scratches from the previous stage while it adds progressive shine. Mechanically polished concrete reaches 60-70 gloss units without sealer application.

For enhanced protection, apply penetrating lithium silicate sealers that maintain breathability, or topical acrylic sealers for higher initial gloss levels. Topical sealers require reapplication every 2-3 years, while penetrating sealers last 3-5 years with proper maintenance.

The essential concrete polishing equipment and labour costs for this multi-stage process vary significantly based on your project size and timeline requirements.

What Does Concrete Polishing Actually Cost

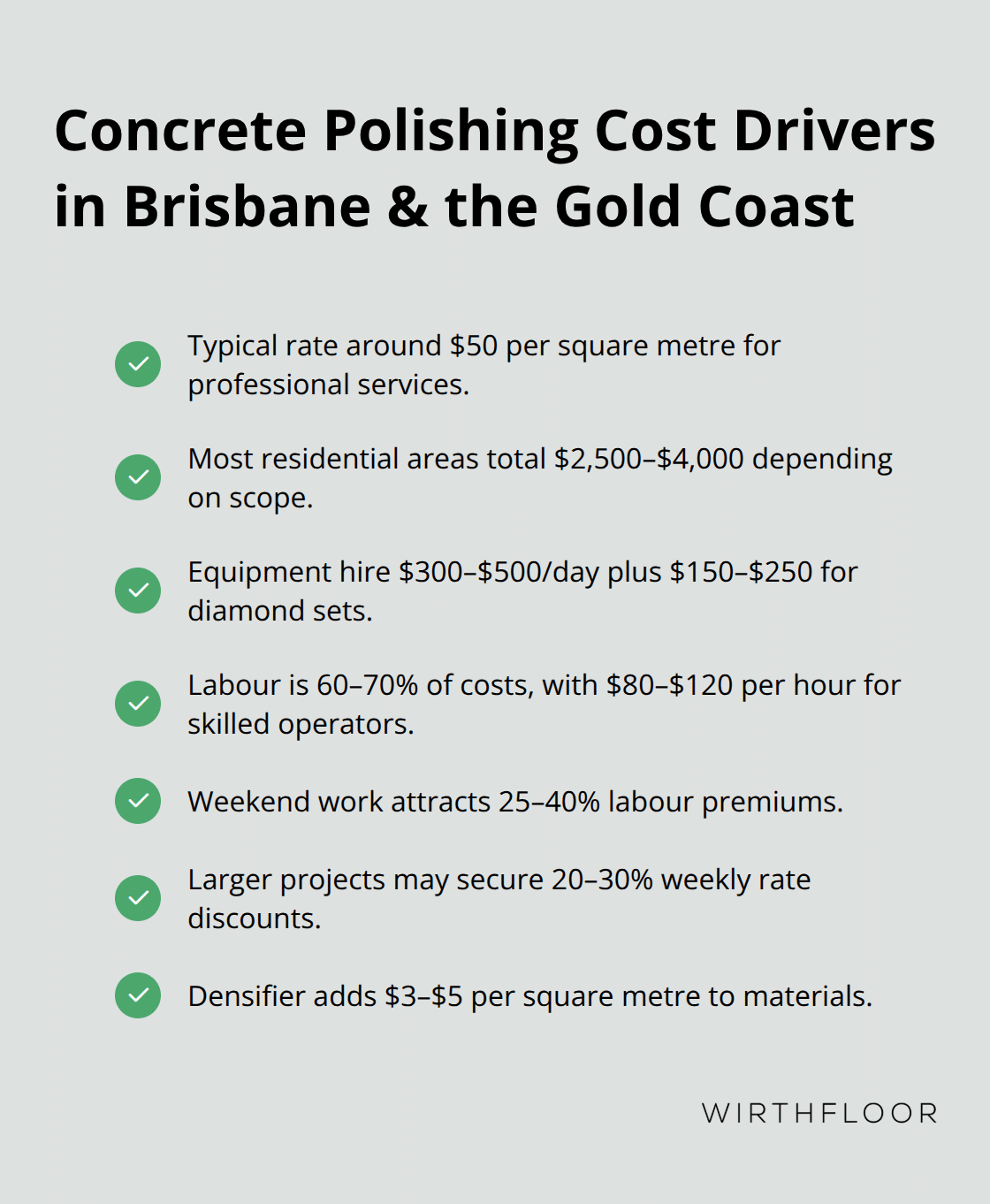

Professional concrete polishing costs $50 per square metre across Brisbane and the Gold Coast, with most residential projects totalling $2,500-4,000 for typical areas. Equipment rental alone runs $300-500 daily for walk-behind grinders, plus $150-250 for diamond tool sets. Labour costs represent 60-70% of total project expenses, with experienced operators who charge $80-120 per hour for multi-stage work.

Project Duration Changes With Slab Condition

A standard 100-square-metre warehouse floor requires 3-4 days for complete work when the concrete condition allows direct progression through grit stages. Poor slab condition doubles this timeline through additional repair work, moisture remediation, and extra passes. Damaged concrete with extensive cracks or contamination adds 2-3 days for proper preparation before work begins.

Weekend work increases labour costs by 25-40%, which makes weekday schedules the most cost-effective approach for commercial properties. Contractors often charge premium rates for after-hours work (particularly in retail spaces that operate during standard business hours).

Equipment and Material Expenses

Diamond tooling represents a significant material expense, with complete grit sequences that cost $800-1,200 per 100-square-metre project. Metal-bonded diamonds for initial stages cost $40-60 per disc, while resin-bonded diamonds for final stages run $25-35 per disc. Densifier application adds $3-5 per square metre to material costs.

Professional-grade equipment rental includes planetary grinders, dust collection systems, and edge work tools. Daily rental rates vary based on equipment size and local availability, with larger projects that qualify for weekly rates at 20-30% discounts.

Long-Term Value Exceeds Initial Investment

Polished concrete floors last 20+ years with minimal maintenance compared to 5-7 year replacement cycles for carpet or vinyl options. Annual maintenance costs average $2-3 per square metre for professional clean and reseal versus $8-12 per square metre for alternative replacement reserves.

Property values can increase with quality installation according to Queensland real estate data, while energy costs drop 10-20% through improved light reflection and thermal mass performance. The 10-year total cost of ownership for polished concrete averages 40% less than comparable options when you factor in replacement, maintenance, and energy benefits.

Final Thoughts

Polishing existing concrete slabs delivers superior value compared to complete floor replacement across Brisbane properties. The process costs 40-60% less than new installation while it provides identical durability and aesthetic results. Property owners save thousands in demolition, disposal, and material expenses when they work with existing foundations.

Professional assessment prevents costly mistakes that plague DIY attempts. Concrete strength testing, moisture evaluation, and surface defect analysis determine project feasibility before equipment rental begins. These steps prevent failed finishes, wasted materials, and additional repair costs that exceed professional service fees.

Brisbane property owners should schedule site evaluations during dry weather periods when moisture readings provide accurate baseline data (commercial spaces benefit from weekday schedules to minimise business disruption). We at Wirth Floor provide comprehensive assessments and professional concrete polishing throughout Brisbane and the Gold Coast. Contact us for detailed project quotes and timeline estimates based on your specific requirements.