Polished concrete transforms ordinary floors into stunning, durable surfaces that last for decades. This flooring solution combines functionality with modern aesthetics.

We at Wirth Floor see growing demand for concrete polishing services across Brisbane’s commercial and residential properties. The process delivers exceptional value compared to traditional flooring options.

What Exactly Is Concrete Polishing

Concrete polishing transforms rough concrete into a mirror-like surface through mechanical grinding with diamond-embedded tools. The process starts with coarse grinding to remove surface imperfections, then progresses through finer grits that reach up to 3000-grit diamonds. Professional contractors use specialised machines that apply consistent pressure while water cools the diamonds and controls dust. The HIPERFLOOR system represents true mechanical polishing and creates surfaces approximately ten times harder than standard concrete. This method differs completely from topical coatings that simply sit on the surface.

Shine Levels and Finish Options

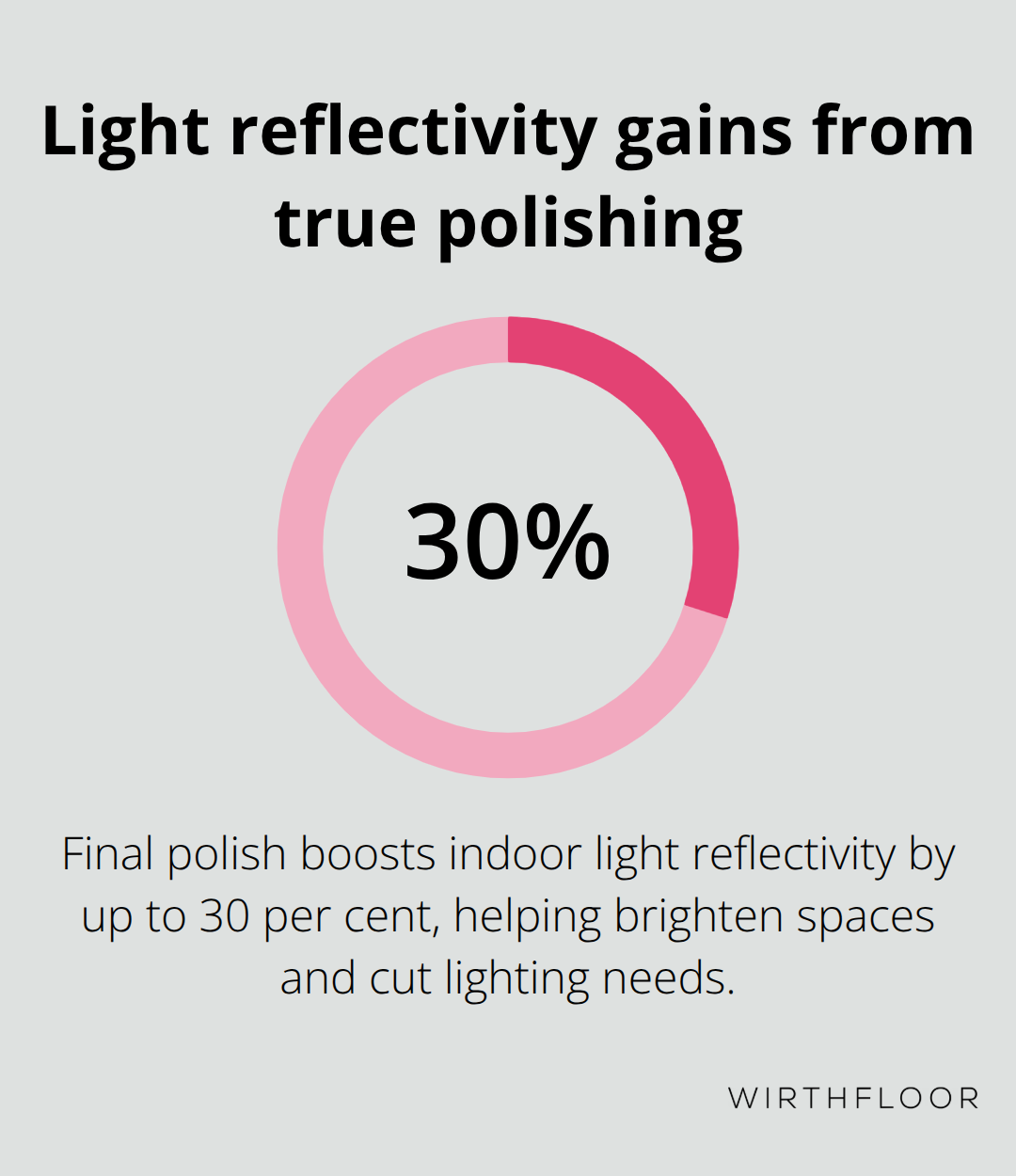

Professional polishing offers three distinct finish levels. Cream finish reveals minimal aggregate with a subtle sheen, perfect for retail spaces that require sophisticated aesthetics. Salt and pepper finish exposes small aggregates and creates texture, ideal for warehouses that need slip resistance. Full aggregate exposure showcases the concrete’s natural stone content, popular in showrooms and modern homes. Each level requires different grinding depths and diamond sequences. The final polish can achieve light reflectivity improvements up to 30 per cent (significantly brightening interior spaces without additional lighting costs).

True Polishing Versus Coating Systems

Mechanical polishing creates permanent results that last decades, while coating systems require reapplication every five years in high-traffic areas. Polished concrete costs between 80 to 110 dollars per square metre compared to grinding and sealing at 50 to 75 dollars per square metre. However, coating systems fail under heavy loads and show wear patterns within months. True polishing penetrates the concrete matrix and makes the surface progressively harder with each diamond pass. Coating systems trap moisture beneath (leading to delamination and costly repairs) that polished concrete avoids entirely.

Professional Equipment and Techniques

Modern polishing machines deliver consistent results that DIY methods cannot match. Professional contractors operate planetary grinders that maintain uniform pressure across the entire surface. These machines feature multiple grinding heads that rotate at precise speeds while the main plate rotates in the opposite direction. Water-cooled diamond tools prevent overheating and extend tool life significantly. Professional teams also use dust collection systems that meet Australian workplace safety regulations, creating safer work environments and cleaner job sites.

The benefits of professional concrete polishing extend far beyond surface appearance, making this investment particularly attractive for property owners who prioritise long-term value.

Why Professional Polished Concrete Outperforms Other Flooring

Professional concrete polished surfaces deliver unmatched durability that outlasts traditional materials by decades. The mechanical process creates surfaces with Mohs hardness ratings of 7-9, compared to 3-4 for traditional finished concrete, which makes them virtually indestructible under normal use.

Hardwood floors require refinishment every seven to ten years, while carpet needs replacement every five to seven years. Polished concrete maintains its appearance for over 20 years with proper installation. The diamond process densifies the concrete matrix and creates a surface that resists scratches, stains, and impact damage.

Commercial Performance Data Shows Clear Winners

Commercial facilities report zero floor replacement costs after 15 years of heavy traffic, while timber floors show significant wear within five years. The diamond process transforms ordinary concrete into surfaces that handle forklift traffic, heavy machinery, and constant foot traffic without deterioration.

Retail stores with polished concrete floors maintain their original appearance after five years of operation, while vinyl and timber surfaces require partial replacement. Warehouses experience no surface degradation even under extreme loading conditions (making polished concrete the preferred choice for industrial applications).

Maintenance Requirements Drop to Almost Nothing

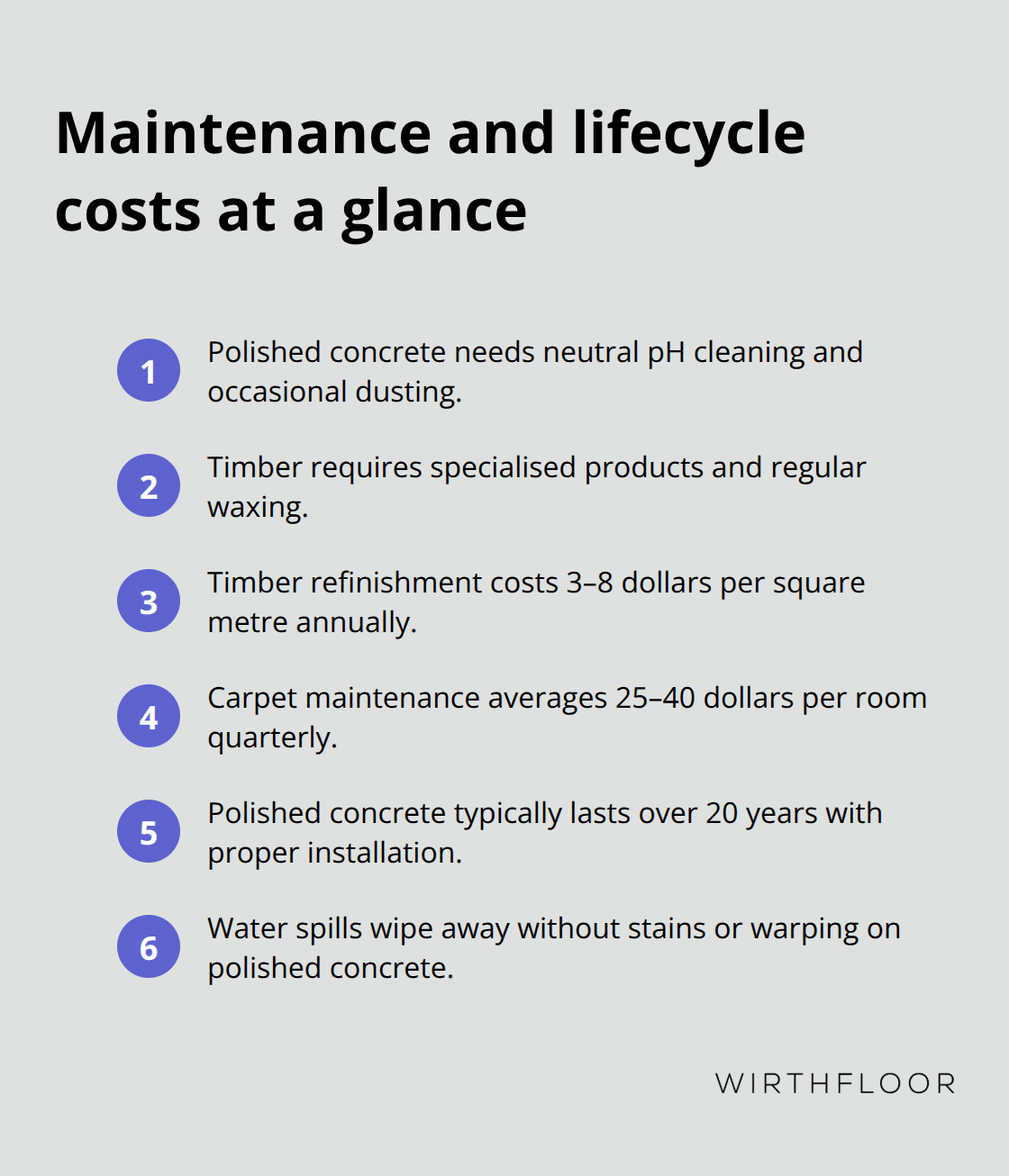

Polished concrete requires only neutral pH cleaners and occasional dust removal, which eliminates expensive maintenance contracts. Timber floors need specialised products, regular wax application, and professional refinishment that costs between 3 to 8 dollars per square metre annually.

Carpet maintenance averages 25 to 40 dollars per room quarterly, plus replacement costs. Businesses with polished concrete report significantly lower maintenance costs compared to other options. Water spills clean up instantly without stains or warping, unlike timber that swells and requires board replacement.

Total Ownership Costs Favour Concrete Every Time

Installation costs range from 80 to 110 dollars per square metre, while quality timber exceeds 150 dollars per square metre with installation. Over 20 years, polished concrete total ownership costs remain below 120 dollars per square metre, while timber reaches 300 dollars per square metre with refinishment and maintenance.

The thermal mass properties of concrete allow it to absorb, store and release heat effectively. Property values increase with polished concrete installation and provide higher returns on investment compared to traditional materials that depreciate rapidly.

These performance advantages make the choice between polished concrete and other flooring options straightforward, but professional services become necessary when specific applications and site conditions require expert installation and the right equipment.

When Does Professional Polishing Make Sense

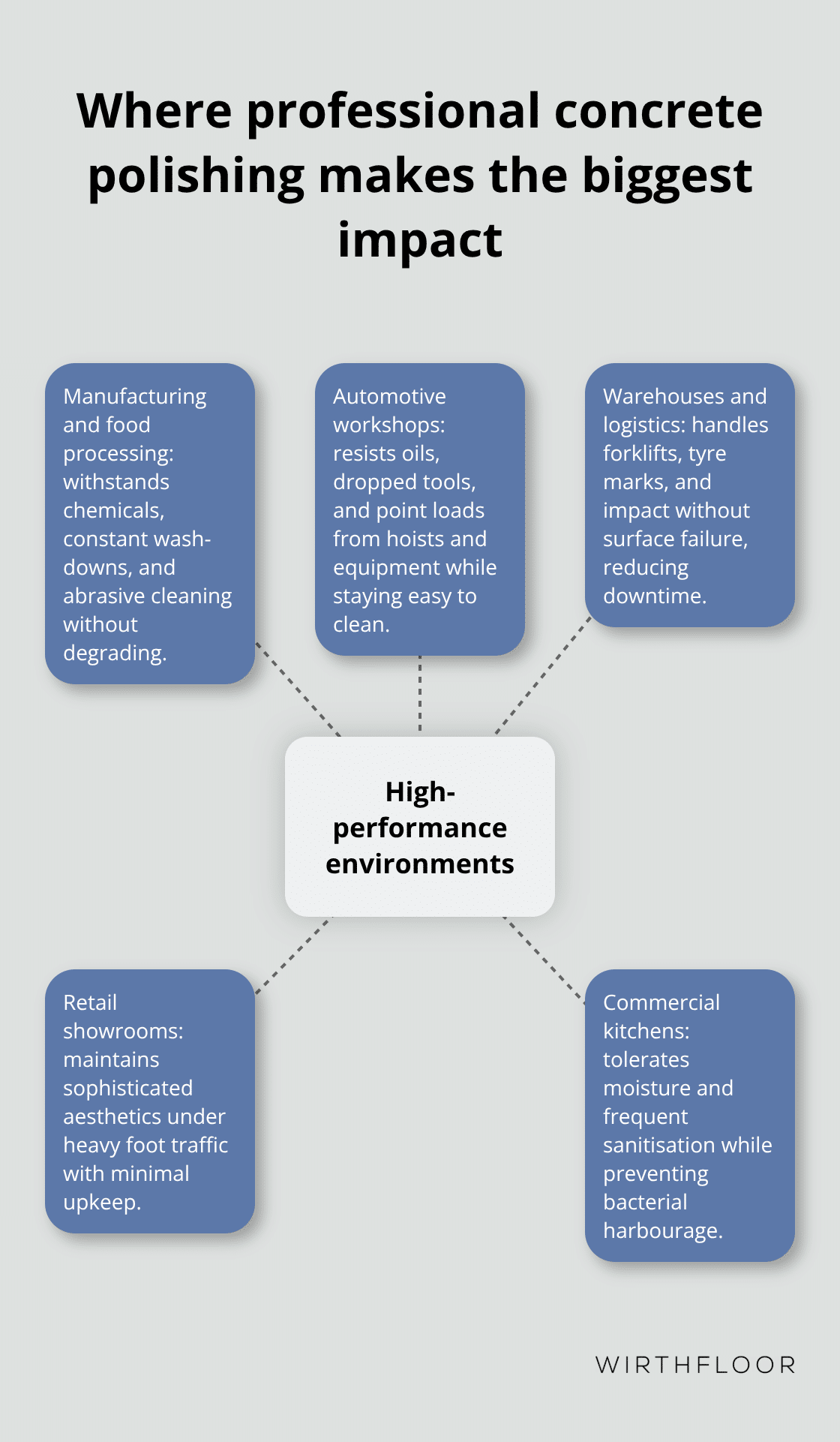

Professional concrete polishing delivers exceptional results in specific environments where durability and performance matter most. Manufacturing facilities, automotive workshops, and food processing plants require surfaces that withstand chemical spills, heavy machinery, and constant cleaning without deterioration. These environments demand superior hardness that only mechanical polishing achieves, compared to limestone’s softer aggregate rating of 3-4 on the Mohs scale.

Warehouses that handle forklifts and heavy equipment benefit from polished concrete’s resistance to tyre marks and impact damage that destroys other floors within months. Retail showrooms with high foot traffic report minimal maintenance needs, as polished concrete lasts 20+ years compared to most flooring materials that need replacement every 5-15 years.

Commercial Spaces That Benefit Most

Medical facilities and diagnostic centres increasingly choose polished concrete for its VOC-free properties and resistance to bacteria growth. The seamless surface eliminates grout lines where contaminants accumulate, which makes cleaning protocols more effective. Restaurant kitchens and commercial food preparation areas benefit from moisture resistance and the ability to withstand frequent sanitisation without surface degradation. Automotive service centres report significant maintenance savings because oil spills clean instantly without stains or penetration into the surface (unlike porous materials that absorb contaminants permanently).

Residential Applications Worth Consideration

Modern homes with open-plan designs showcase polished concrete’s aesthetic appeal while they reduce maintenance requirements to nearly zero. Kitchens with polished concrete floors handle spills, dropped items, and heavy appliance movement without damage, which eliminates the warping and stains common with timber. Bathrooms benefit from moisture resistance that prevents mould growth and structural damage associated with traditional materials. Properties with radiant heating systems maximise efficiency through concrete’s thermal mass ability to absorb, store and release heat (reducing energy costs significantly).

Site Conditions That Favour Professional Installation

Existing concrete slabs in good condition provide the ideal foundation for professional polishing services. Contractors assess slab thickness, aggregate quality, and structural integrity before they recommend polishing. New construction projects benefit from coordination between concrete placement and polishing teams to achieve optimal results. Properties with consistent floor levels across large areas maximise the efficiency of professional equipment and reduce installation costs per square metre.

Final Thoughts

Professional concrete polishing services deliver unmatched durability, minimal maintenance requirements, and superior cost-effectiveness compared to traditional materials. The mechanical diamond process creates surfaces that last over 20 years while timber and carpet require replacement every 5-10 years. Commercial facilities report zero floor replacement costs after 15 years of heavy traffic, while residential properties benefit from moisture resistance and thermal efficiency.

Professional installation remains essential for optimal results. Specialised equipment, proper diamond sequences, and expert technique separate successful projects from failed attempts. DIY methods cannot match the consistent pressure and precision that professional contractors deliver through planetary grinders and water-cooled diamond systems (which maintain uniform surface quality across entire projects).

Property owners should evaluate their existing concrete conditions, traffic requirements, and long-term maintenance goals when they consider concrete polishing services. We at Wirth Floor create custom polished concrete solutions that combine durability with modern aesthetics for commercial and industrial clients. Our team serves Brisbane, Gold Coast, and Sunshine Coast regions with professional expertise and proven results.