Polished concrete has become the go-to flooring choice for property owners across Brisbane, Gold Coast, and Sunshine Coast. Whether you’re renovating a retail space, upgrading a warehouse, or finishing a new home, understanding the different types of polished concrete floors helps you make the right decision for your project.

At Wirth Floor, we’ve installed hundreds of polished concrete floors, and we’ve seen firsthand how the right finish transforms a space. This guide breaks down your options so you can choose what works best for your needs and budget.

Understanding Your Polished Concrete Finish Options

The finish you select determines how your floor looks, performs, and ages over time. Three primary finish categories exist, each suited to different spaces and budgets. High-gloss finishes deliver maximum light reflection and visual impact, making them popular in retail showrooms and hospitality venues where aesthetics matter. High-gloss polished concrete reflects up to 30% more light than unpolished floors, which directly reduces lighting costs in commercial spaces. The trade-off involves maintenance-glossy surfaces show dust and footprints more readily, requiring weekly damp mopping with a neutral pH cleaner to maintain appearance.

High-Gloss and Salt and Pepper Finishes

Salt and pepper finishes fall into the high-gloss category and have become the standard choice for restaurants and shopping malls because the speckled appearance hides minor imperfections while maintaining that upscale shine. These finishes require expert workmanship due to the complexity of exposing finer aggregates, and they typically cost more than cream polished concrete options. The reflective surface makes merchandise stand out and the space feel larger, which directly influences customer perception and sales performance in retail environments.

Matte and Satin Finishes for Practical Spaces

Matte and satin finishes expose less aggregate, creating a more subdued appearance that works well in warehouses, offices, and modern residential spaces. These finishes require less frequent cleaning and don’t show dust as visibly, making them practical for high-traffic industrial areas where maintenance budgets are tight. The reduced glare prevents eye strain during long shifts and the floor withstands heavy machinery without showing damage as readily.

Decorative Polished Concrete with Exposed Aggregates

Decorative polished concrete with exposed aggregates-granite, quartz, or recycled glass-creates a distinctive look that commands attention in galleries, hotels, and premium retail environments. Exposed aggregate finishes take longer to install and cost more than standard salt and pepper options, but the granite-like appearance justifies the investment for properties where first impressions drive business. The exposed finish is also more skid-resistant than high-gloss options, making it safer for wet environments like commercial kitchens and bathroom areas.

Selecting the Right Finish for Your Project

High-gloss works best in spaces where light reflection reduces energy costs and visual appeal attracts customers. Retail showrooms on the Gold Coast benefit significantly from this approach because the reflective surface makes merchandise stand out and the space feel larger. Satin and matte finishes suit functional spaces where durability and low maintenance outweigh visual drama. Warehouses and manufacturing facilities on the Sunshine Coast often select matte finishes because the reduced glare prevents eye strain during long shifts and the floor withstands heavy machinery without showing damage as readily. Decorative aggregate finishes command premium pricing but they add genuine value to hospitality and retail projects where ambience influences customer perception.

When you plan your project, consider foot traffic patterns, existing lighting, and your maintenance capacity before committing to a finish. A showroom in Brisbane with natural light might achieve stunning results with high-gloss, while a warehouse with fluorescent lighting gains nothing from that extra shine and everything from a practical matte finish. The finish you choose today shapes how your floor performs for years to come, which is why understanding these options matters before you move forward with installation.

Where Polished Concrete Delivers Real Results

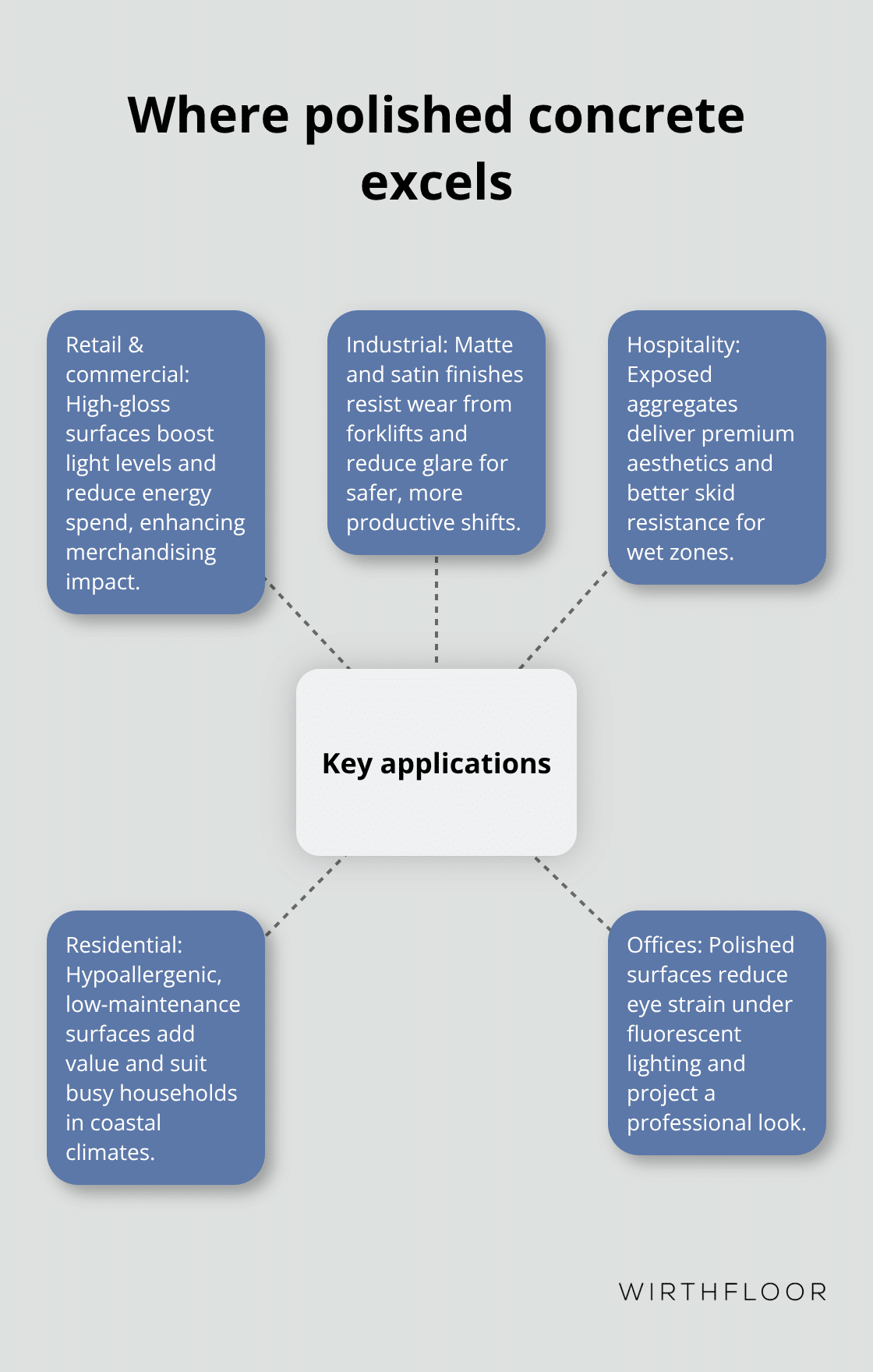

Polished concrete performs differently across industries because each sector faces unique demands. Retail showrooms on the Gold Coast prioritise visual impact and reduced energy costs, while warehouses on the Sunshine Coast need durability under heavy machinery and minimal maintenance overhead. Hospitality venues require floors that withstand constant foot traffic and cleaning cycles without losing their appeal. Understanding how polished concrete actually performs in these real-world scenarios helps you invest wisely rather than guessing what might work.

Retail and Commercial Spaces Benefit from Light Reflection

Retail environments gain measurable advantages from polished concrete’s reflective properties. High-gloss finishes reflect up to 30% more light than standard concrete, which directly reduces artificial lighting requirements and cuts energy bills. A shopping mall or retail showroom on the Gold Coast can lower lighting costs by hundreds of dollars monthly across a large floor area. The reflective surface also makes merchandise appear brighter and more appealing, which influences customer perception and purchasing behaviour. Salt and pepper finishes deliver this light reflection while hiding minor dust and footprints, making them ideal for spaces where appearance matters constantly. Office buildings and corporate environments benefit similarly because the polished surface reduces eye strain under fluorescent lighting and creates a professional atmosphere that impresses clients. The non-porous surface resists staining from spills, which is critical in busy commercial kitchens attached to restaurants. Weekly damp mopping with neutral pH cleaner maintains the finish without expensive specialist equipment, keeping maintenance budgets realistic for facility managers.

Industrial Facilities Prioritise Durability Over Aesthetics

Warehouses and manufacturing plants on the Sunshine Coast need floors that survive heavy machinery, forklift traffic, and constant impacts without deteriorating. Matte and satin finishes excel here because they hide wear patterns and don’t show scratches as obviously as high-gloss options. The mechanically polished surface hardens through a densifying chemical reaction that fuses cement paste and aggregate together, creating exceptional wear resistance that outlasts vinyl, carpet, or standard sealed concrete by years. A warehouse floor can operate for decades with minimal damage when properly installed and maintained. The reduced glare from matte finishes prevents eye strain during long shifts, which directly impacts worker safety and productivity. Industrial facilities avoid the high-gloss finish because the reflective surface creates glare problems under warehouse lighting and offers no practical benefit in spaces where function ranks above aesthetics. Epoxy coatings sometimes marketed as polished concrete alternatives typically fail faster in these environments due to moisture and alkalinity issues, so true mechanical polishing outperforms coated options long-term. Spot treatment of spills with neutral pH cleaner prevents staining, and the non-porous surface resists dust accumulation that plagues traditional concrete floors.

Hospitality and Residential Properties Demand Aesthetic Appeal with Practicality

Hotels, restaurants, and premium residential projects require floors that look exceptional while handling daily wear from guests and residents. Exposed aggregate finishes with granite or quartz create distinctive visual impact that justifies premium pricing in these settings. The speckled appearance hides minor imperfections while the polished surface maintains that luxury feel that guests expect. These finishes also provide better skid resistance than high-gloss options, making them safer for wet areas like bathroom floors and commercial kitchen zones. Residential properties in Brisbane renovations increasingly select salt and pepper finishes because the upscale appearance adds genuine property value without the maintenance burden of other premium flooring options. The hypoallergenic, non-porous surface reduces dust and dander, which benefits residents with allergies. Unlike timber or carpet that absorb moisture and mould spores, polished concrete resists moisture penetration and stays hygienic in humid coastal climates. A damp cloth and appropriate neutral pH cleaner maintain the finish weekly, making it practical for busy households and hospitality operations with tight cleaning schedules. Decorative options including dyed or stained polished concrete allow colour customisation that matches branding in hotels and restaurants, creating cohesive design narratives that standard flooring cannot achieve.

Each industry sector demands different performance characteristics from its flooring, which means your choice of finish directly impacts how well your investment performs over time. The next section examines the maintenance and durability factors that determine whether your polished concrete floor remains an asset or becomes a liability.

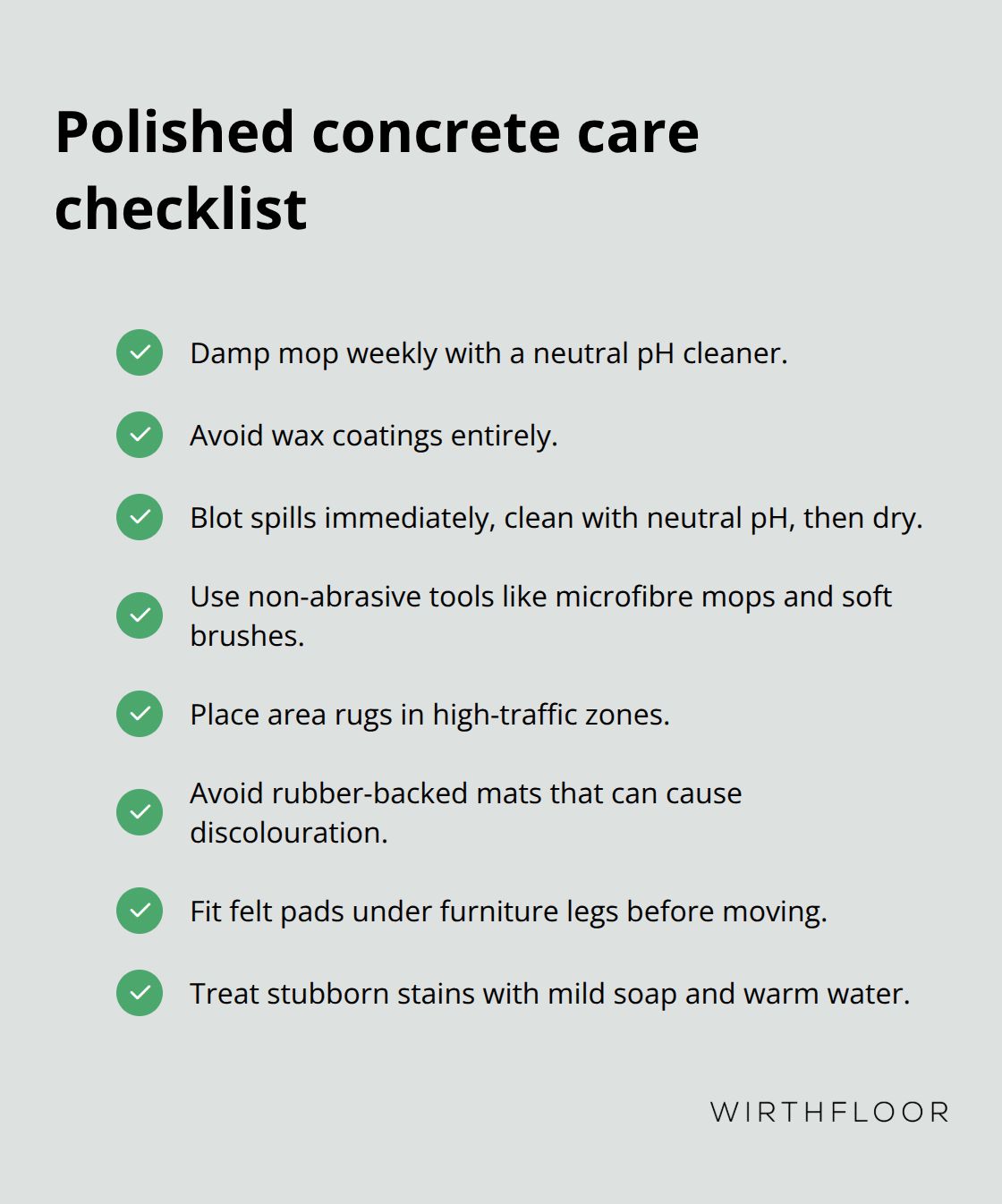

How to Keep Polished Concrete Looking New

Polished concrete demands far less maintenance than most property owners expect, which is precisely why it outperforms traditional flooring in high-traffic environments across Brisbane, Gold Coast, and Sunshine Coast. A single habit-weekly damp mopping with neutral pH cleaner-removes dust and footprints without damaging the surface and prevents 90% of appearance issues before they start. Wax coatings destroy the polished finish and create build-up that requires expensive stripping to restore, so avoid them entirely. Spills need immediate attention with a cloth and neutral pH cleaner, followed by drying to prevent water spots. Matte and satin finishes hide dust more effectively than high-gloss options, so if your budget favours low-maintenance performance, these finishes require genuinely less frequent cleaning while delivering identical durability. Mild soap with warm water and gentle brushing solves most stubborn stains without harsh chemicals that damage the surface. Area rugs or mats protect high-traffic zones, but rubber-backed varieties cause discolouration and should be avoided. Felt pads under furniture prevent scratches when you move pieces across the floor.

Daily and Weekly Care Routines

Dry-mopping removes loose dirt and debris before they scratch the finish. Damp mopping with neutral pH solution lifts dirt without harming the surface, and this routine takes minimal time compared to other flooring types. Non-abrasive tools (microfibre mops, soft brushes) protect the polished layer from damage. Spills on polished concrete respond well to immediate blotting and cleaning with neutral pH cleaner, then drying to avoid water spots that mar the appearance.

Protecting Your Floor from Damage

High-traffic areas benefit from area rugs that reduce wear on the most-used zones. Felt pads under furniture legs prevent scratches when you move pieces across the floor. Rubber-backed mats cause discolouration and should be replaced with alternatives that won’t stain the surface.

Sealing for Extended Longevity

Sealing frequency depends on foot traffic intensity and your specific climate conditions on the coast, with water-based sealers requiring reapplication every 5–10 years. Solvent-based sealers last 3–4 years between applications and deliver more durable finishes than water-based alternatives, which offer better environmental credentials. Industrial facilities on the Sunshine Coast frequently report zero floor replacement costs over 15+ years because mechanically polished concrete simply doesn’t fail like coated systems do when exposed to moisture and alkalinity.

Long-Term Cost Advantages

Polished concrete floors outlast vinyl, carpet, and timber by decades when properly maintained, making them the most cost-effective choice over a 20-year lifecycle. The mechanically polished surface hardens through densification, creating exceptional wear resistance that actually improves with age rather than degrading. Retail spaces in Brisbane see measurable payback within 6–8 years through reduced lighting costs from the reflective surface, and that financial advantage compounds as maintenance remains minimal. Timber requires refinishing every 5–7 years and absorbs moisture in coastal humidity, carpet needs replacement every 8–10 years and harbours dust and allergens, vinyl deteriorates under heavy machinery and shows every footprint, while polished concrete performs identically at year one and year twenty with nothing more than a damp cloth and routine sealing.

Final Thoughts

Polished concrete delivers measurable advantages across retail, industrial, and residential projects throughout Brisbane, Gold Coast, and Sunshine Coast. High-gloss finishes reduce lighting costs through superior light reflection, salt and pepper options hide imperfections while maintaining upscale aesthetics, and matte finishes prioritise durability in heavy-traffic warehouses. Exposed aggregate varieties command premium pricing because they create distinctive visual impact that justifies investment in hospitality and retail settings, and each type of polished concrete floor serves specific performance demands that directly determine how well your investment performs over decades.

The real advantage emerges over time as polished concrete outlasts vinyl, carpet, and timber by years while requiring nothing more than weekly damp mopping with neutral pH cleaner. Industrial facilities report zero floor replacement costs over 15+ years because mechanically polished surfaces simply don’t fail like coated systems when exposed to moisture and coastal humidity. Retail spaces see measurable payback within 6–8 years through reduced lighting costs alone, and that financial advantage compounds as maintenance remains minimal.

Property owners across the coast should contact Wirth Floor to discuss their specific project requirements and explore which types of polished concrete floors suit their needs. We specialise in polished concrete and epoxy flooring solutions tailored to commercial, industrial, and residential projects, delivering exceptional craftsmanship that transforms your flooring investment into a long-term asset performing reliably for decades.